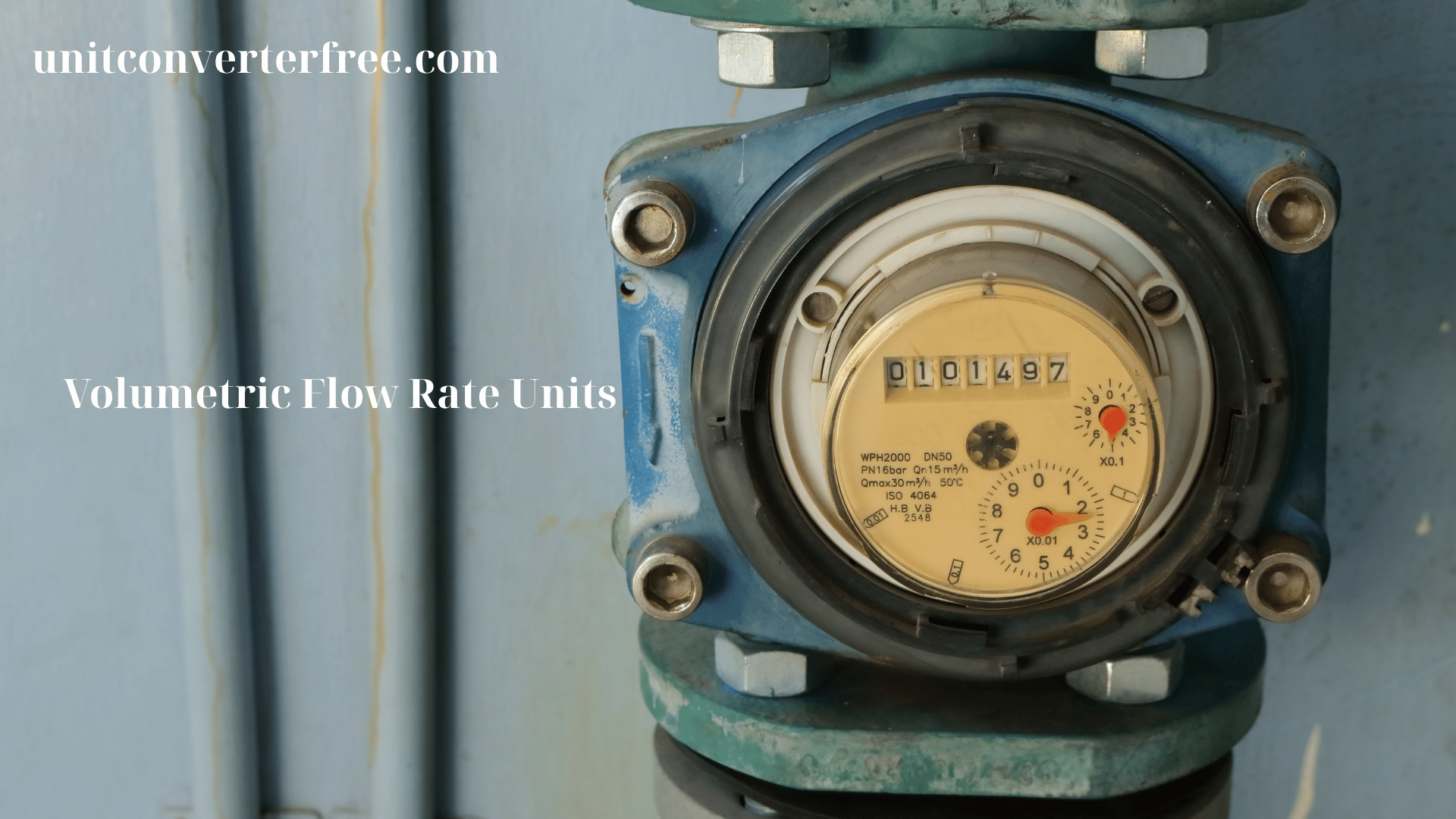

In the world of fluid mechanics and process engineering, accurately measuring the movement of liquids and gases is critical to system performance, safety, and efficiency. One of the most fundamental measurements in this field is the volumetric flow rate, which refers to the volume of fluid flowing through a cross-section of a system per unit time. Whether it’s water in a pipeline, air in a ventilation system, or chemicals in an industrial reactor, understanding and calculating flow is essential—and this starts with using the correct volumetric flow rate units.

Volumetric flow rate units provide the standard by which fluid movement is quantified, compared, and controlled across a wide range of applications and industries. These units vary by region and industry preference, with both SI (metric) and imperial systems in use. Examples include cubic meters per second (m³/s), liters per minute (L/min), cubic feet per minute (CFM), and gallons per minute (GPM), among others.

Selecting the correct volumetric flow rate units is not just a matter of convenience—it directly impacts engineering calculations, system compatibility, instrumentation, and regulatory compliance. Misinterpreting or misusing these units can lead to costly design errors, operational inefficiencies, and safety hazards.

In this comprehensive guide, we will explore what volumetric flow rate really means, break down the most common volumetric flow rate units, compare their usage across different applications, and provide practical guidance on converting between units. Whether you’re an engineer, technician, student, or industry professional, understanding volumetric flow rate units is key to mastering the principles of fluid dynamics and achieving

What is Volumetric Flow Rate?

Volumetric flow rate is a fundamental concept in fluid mechanics and refers to the volume of fluid passing through a given surface or cross-section per unit of time. In simple terms, it measures how much space a fluid occupies as it flows—not how much it weighs or how fast it moves, but how much volume it displaces over time.

Formula and Components

The volumetric flow rate is typically represented by the symbol Q, and its most common expression is:

Where:

-

Q = Volumetric flow rate (in m³/s, L/min, etc.)

-

A = Cross-sectional area of the pipe or duct (in m²)

-

v = Average velocity of the fluid through the section (in m/s)

This relationship highlights that the flow rate depends both on how fast the fluid is moving and on the size of the channel it’s moving through. For example, a high velocity through a narrow pipe may result in the same volumetric flow rate as a lower velocity through a much wider pipe.

Volumetric vs. Mass Flow Rate

It’s important to distinguish between volumetric flow rate and mass flow rate:

-

Volumetric flow rate concerns the space the fluid occupies (e.g., cubic meters per second).

-

Mass flow rate deals with the mass of fluid passing per unit time (e.g., kilograms per second).

The relationship between them is:

Mass flow rate=Volumetric flow rate×Density

This becomes particularly relevant in gas systems, where the density of the fluid can vary significantly with pressure and temperature, altering the mass but not the volume.

Why It Matters

Understanding volumetric flow rate units allows engineers and technicians to:

-

Properly size pipes, valves, and pumps

-

Ensure systems meet regulatory requirements

-

Maintain efficient and safe operations

-

Compare performance across different systems or locations

It also enables accurate control of process variables in industries ranging from oil and gas to HVAC to pharmaceuticals. Without the right volumetric flow rate units, instrumentation may provide misleading data, leading to errors in system design or operation.

Common Volumetric Flow Rate Units Explained

Understanding volumetric flow rate units is essential for fluid system design, monitoring, and control across various industries. These units provide standardized ways to express how much fluid passes through a system over a given period of time. Depending on the industry and region, both metric (SI) and imperial units are widely used. Knowing how to read, apply, and convert between these units ensures consistent and precise engineering performance.

1. Metric (SI) Volumetric Flow Rate Units

The International System of Units (SI) offers globally accepted standards for measuring volumetric flow. Common SI-based volumetric flow rate units include:

Cubic Meters per Second (m³/s)

-

The SI base unit for volumetric flow rate

-

Typically used in high-flow industrial applications, like water treatment or hydroelectric systems

-

1 m³/s = 1,000 liters per second

Liters per Second (L/s)

-

Common in laboratory and mid-scale industrial systems

-

1 L/s = 0.001 m³/s

Liters per Minute (L/min)

-

Often used in HVAC, automotive, and small-scale applications

-

1 L/min = 0.01667 L/s

Milliliters per Second (mL/s)

-

Used in medical, pharmaceutical, and scientific applications requiring precision

-

1 mL/s = 0.001 L/s

2. Imperial Volumetric Flow Rate Units

Imperial units are widely used in the United States and select industries across the globe. Common imperial volumetric flow rate units include:

Cubic Feet per Minute (CFM)

-

Common in HVAC systems for measuring airflow

-

1 CFM ≈ 0.0283 m³/min

Gallons per Minute (GPM)

-

Widely used in plumbing, water supply systems, and fuel dispensing

-

U.S. gallon is different from U.K. gallon

-

1 GPM (U.S.) ≈ 3.785 L/min

Cubic Inches per Second (in³/s)

-

Useful in detailed engineering analysis or flow modeling in automotive and aerospace fields

-

1 in³/s ≈ 0.01639 L/s

3. Side-by-Side Comparison Table

| Unit | Abbreviation | Metric/Imperial | Equivalent (Approximate) |

|---|---|---|---|

| Cubic meters/second | m³/s | Metric | 1 m³/s = 1,000 L/s |

| Liters/second | L/s | Metric | 1 L/s = 60 L/min |

| Liters/minute | L/min | Metric | 1 L/min = 0.2642 GPM |

| Cubic feet/minute | CFM | Imperial | 1 CFM = 28.3168 L/min |

| Gallons/minute (U.S.) | GPM | Imperial | 1 GPM = 3.78541 L/min |

| Cubic inches/second | in³/s | Imperial | 1 in³/s = 0.01639 L/s |

4. Importance of Choosing the Right Unit

Using the appropriate volumetric flow rate units ensures:

-

System compatibility between different equipment and regions

-

Accurate reporting and data analysis for system performance

-

Ease of communication in international projects and technical documentation

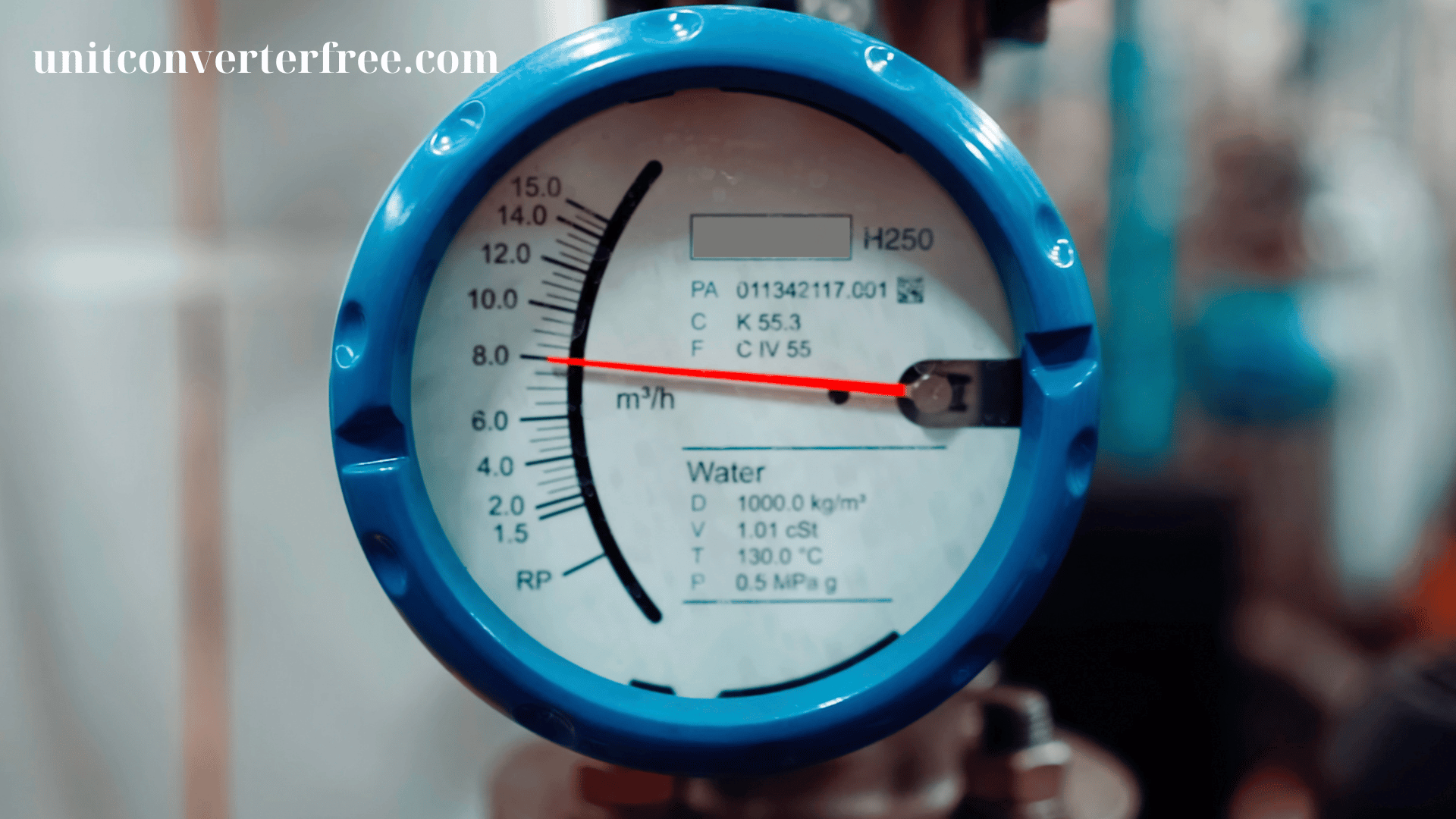

Measurement Instruments and Devices

To ensure the accuracy of any fluid system, selecting the right instrument to measure flow is critical. Different measurement devices are designed for various fluids, pressures, and flow conditions—and the choice often depends on the required volumetric flow rate units, the type of fluid (liquid or gas), and the environment in which the system operates.

Let’s explore the most common devices used to measure volumetric flow rate units and how they function.

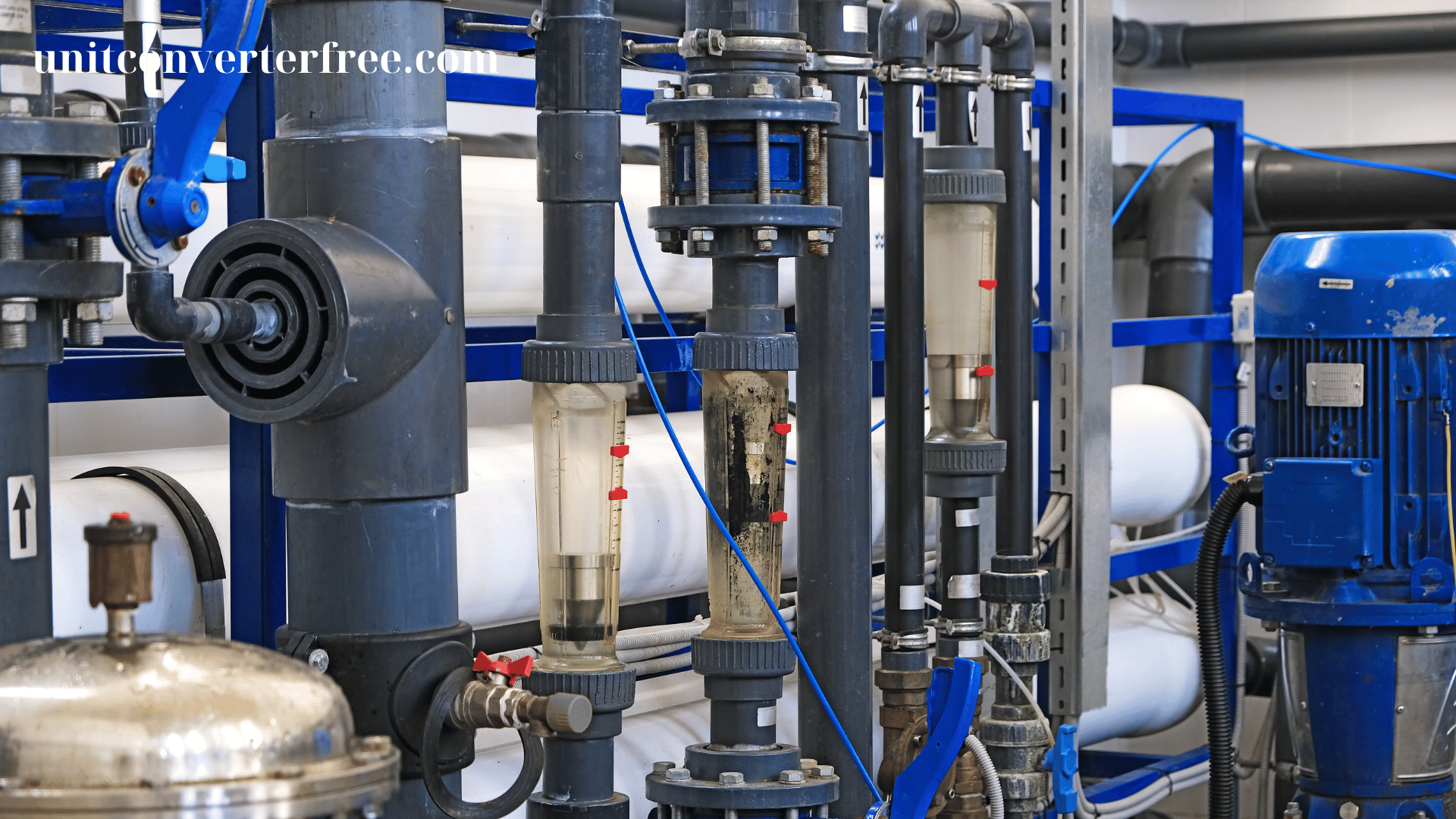

1. Rotameters (Variable Area Flow Meters)

-

How it works: A float rises in a tapered tube as flow increases; its position indicates flow rate.

-

Ideal for: Low-pressure liquid or gas flows in laboratory and industrial setups.

-

Common units displayed: L/min, mL/min, SCFM (standard cubic feet per minute).

-

Advantages: Simple, low-cost, no external power required.

-

Limitations: Less precise under fluctuating pressures or densities.

2. Turbine Flow Meters

-

How it works: Fluid moves a turbine; rotational speed is proportional to flow rate.

-

Ideal for: Clean, low-viscosity fluids in fuel, oil, and water applications.

-

Volumetric flow rate units supported: GPM, L/min, m³/h.

-

Advantages: High accuracy and repeatability.

-

Limitations: Not suitable for contaminated or viscous fluids.

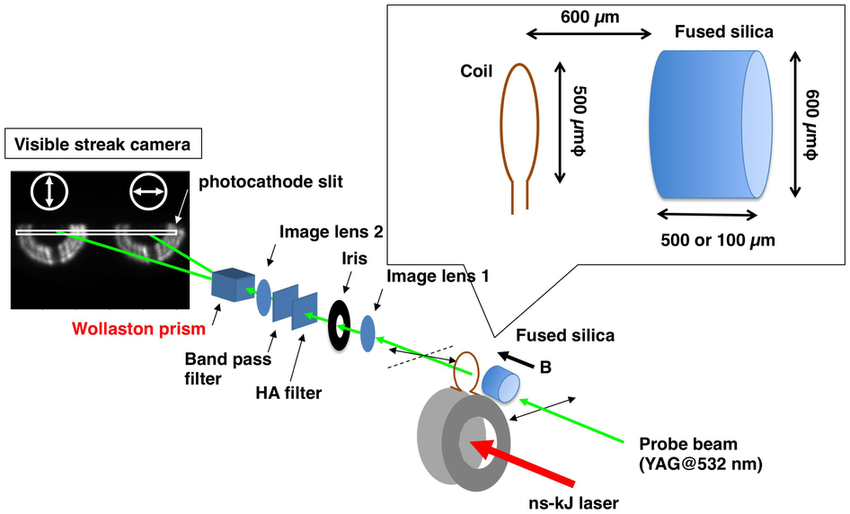

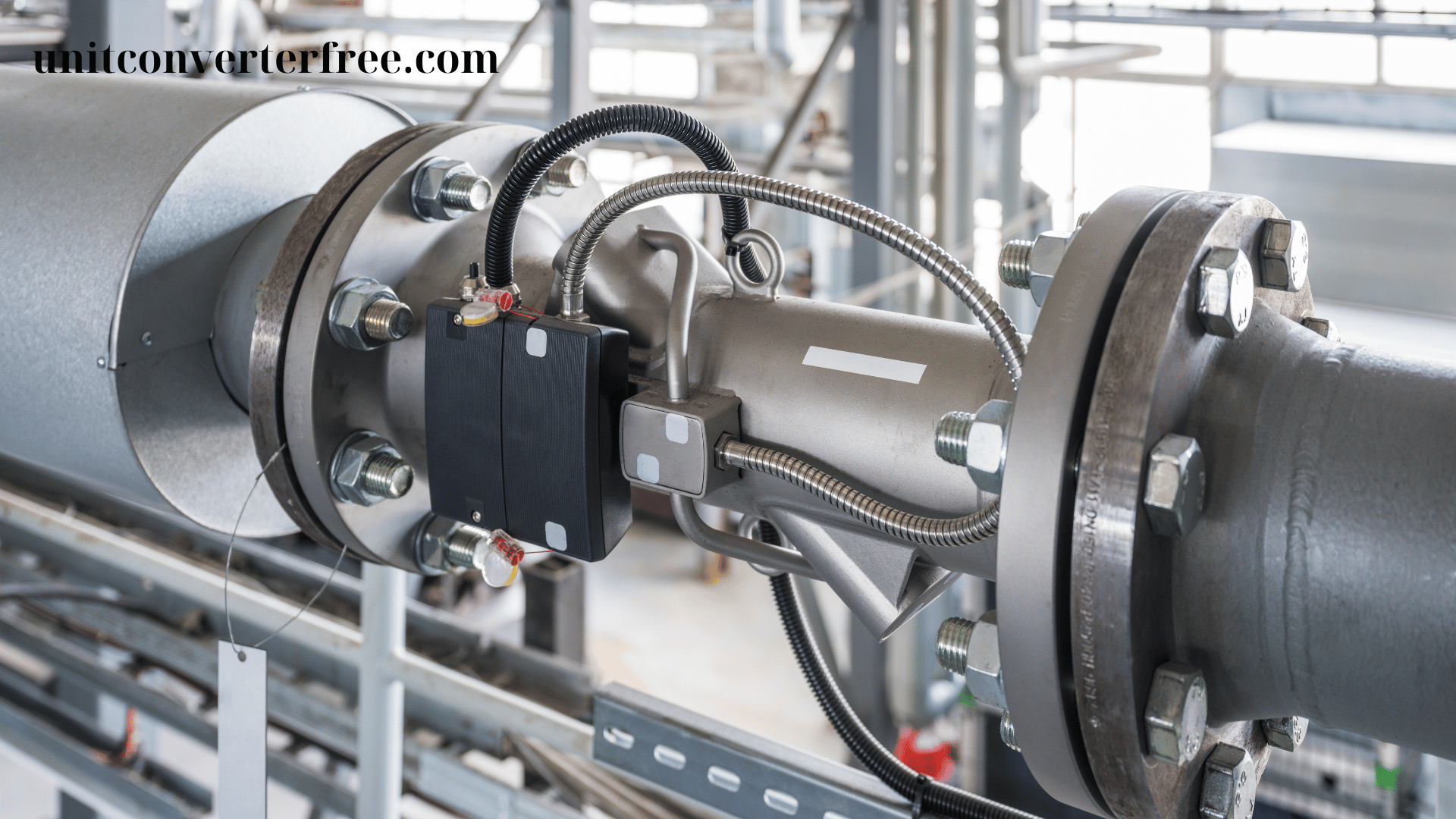

3. Ultrasonic Flow Meters

-

How it works: Measure the time difference between ultrasonic pulses sent upstream and downstream.

-

Ideal for: Non-invasive measurement of large pipe flows or aggressive chemicals.

-

Units displayed: m³/s, L/s, CFM, depending on setup.

-

Advantages: No moving parts, suitable for large or hard-to-reach pipes.

-

Limitations: Accuracy affected by air bubbles and pipe material.

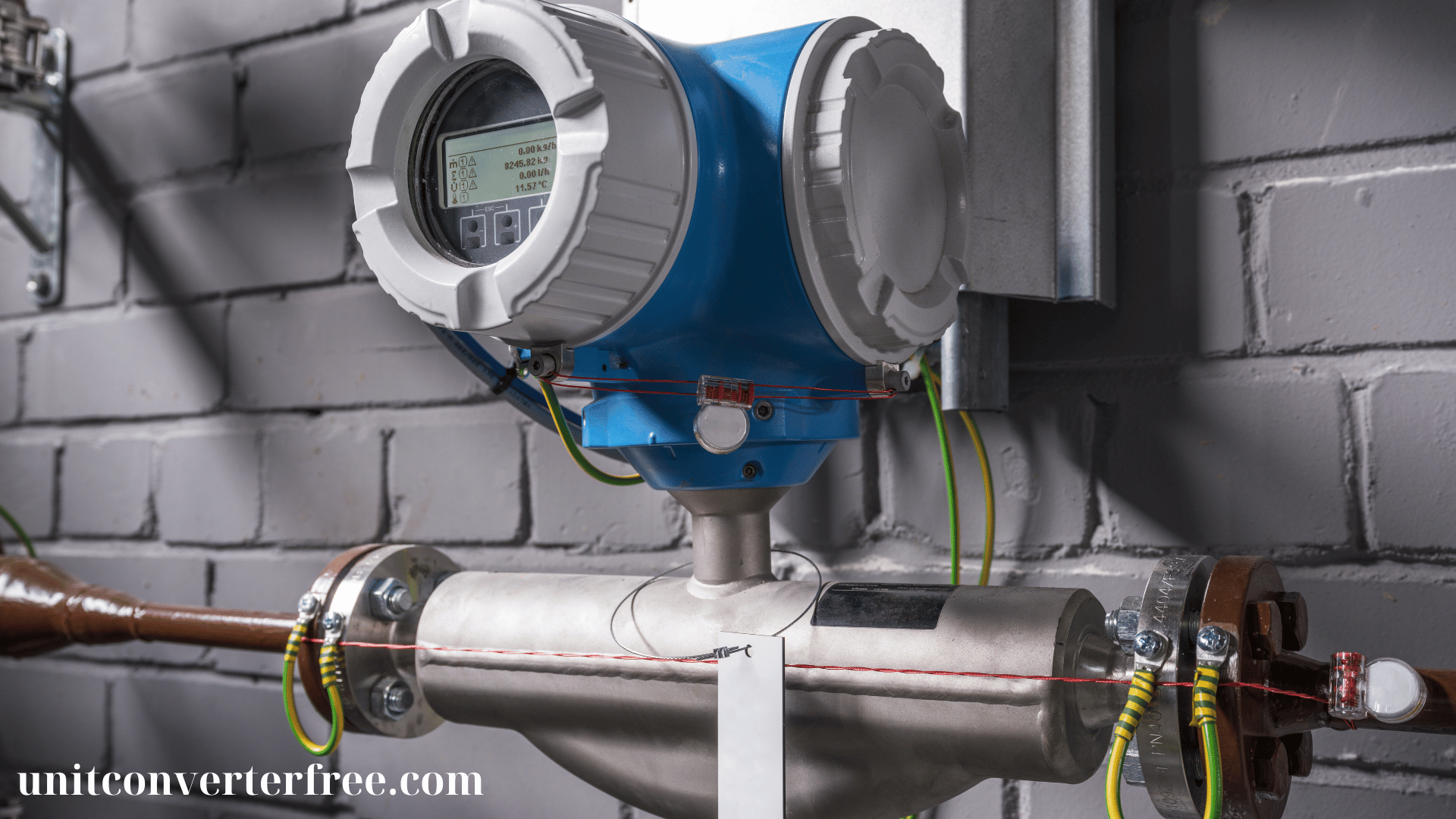

4. Magnetic Flow Meters (Magmeters)

-

How it works: Uses Faraday’s Law—fluid must be conductive to measure voltage induced by flow.

-

Ideal for: Water, slurry, and chemical applications.

-

Volumetric flow rate units shown: L/min, m³/h.

-

Advantages: No pressure drop, accurate in turbulent conditions.

-

Limitations: Cannot measure non-conductive fluids (like oil or gases).

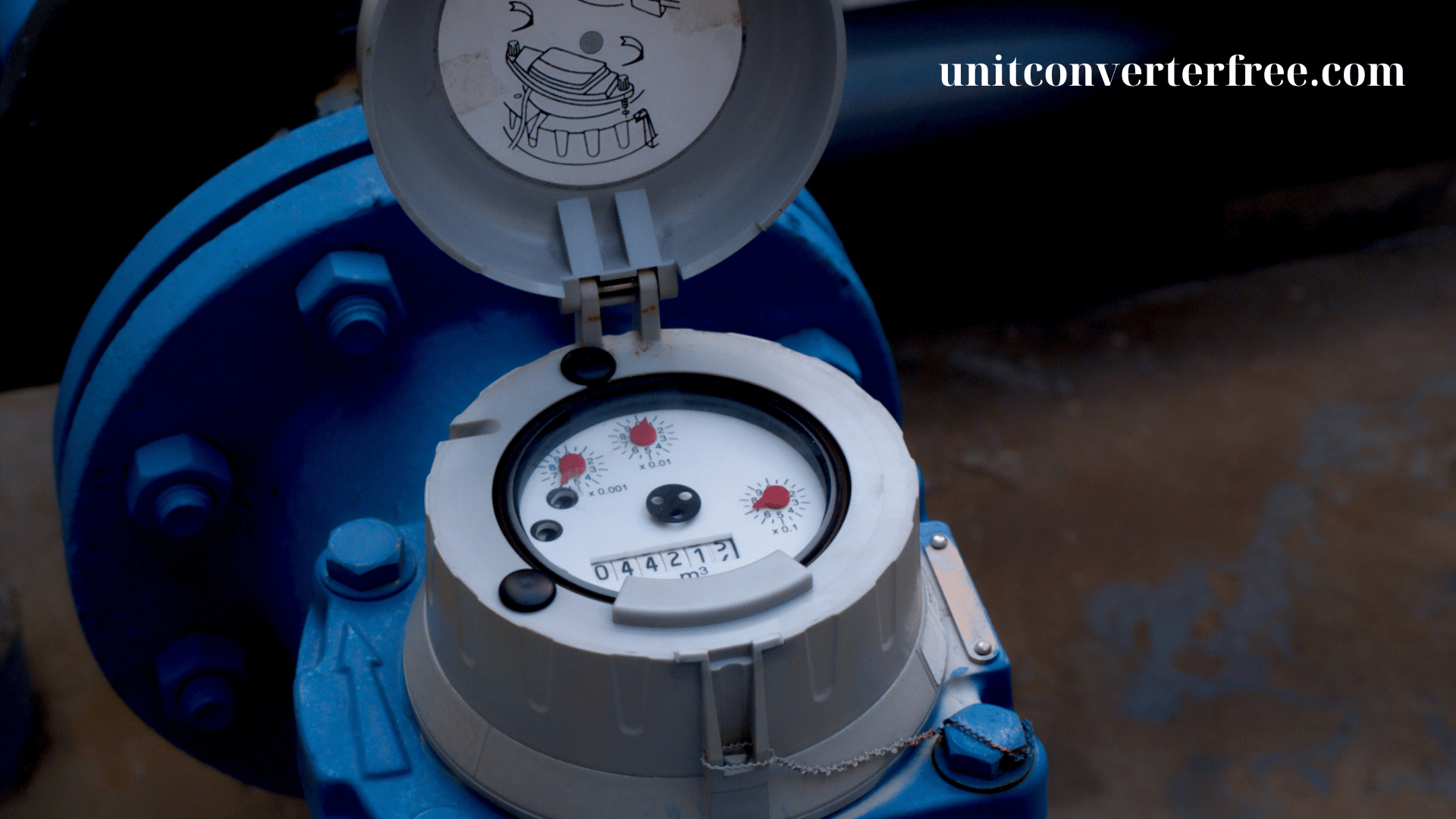

5. Positive Displacement Flow Meters

-

How it works: Traps and counts fixed volumes of fluid with internal moving components.

-

Used for: High-accuracy liquid flow (e.g., fuel dispensing, hydraulic systems).

-

Typical units: L/min, GPM, mL/rev.

-

Advantages: Precise measurement, unaffected by viscosity.

-

Limitations: Not suitable for dirty or particle-laden fluids.

6. Differential Pressure Flow Meters (e.g., Orifice Plates, Venturi Tubes)

-

How it works: Measures pressure drop caused by flow restriction.

-

Suitable for: Wide range of liquids and gases.

-

Commonly calibrated in: m³/s, L/s, GPM, CFM.

-

Advantages: Durable and inexpensive.

-

Limitations: Requires pressure and temperature compensation for accurate readings.

Choosing the Right Instrument Based on Volumetric Flow Rate Units

Selecting a flow measurement device depends on several factors:

-

Fluid type (liquid or gas)

-

Flow range and required accuracy

-

Operating conditions (temperature, pressure, chemical compatibility)

-

Preferred volumetric flow rate units for output and reporting

-

Installation requirements (space, orientation, power)

Accurate flow monitoring is essential for efficient system operation, process control, and safety. By understanding how each instrument reports volumetric flow rate units, professionals can ensure better integration and performance across systems.

Applications Across Industries

The concept of volumetric flow rate is applied in nearly every industry where fluids or gases are moved, measured, or managed. Choosing the correct volumetric flow rate units is crucial for compliance, process efficiency, and safety. Each industry often uses specific units based on historical standards, regional preferences, and regulatory requirements.

Below is a detailed breakdown of how volumetric flow rate units are applied across key industries.

1. Oil and Gas Industry

-

Applications: Crude oil transport, natural gas pipelines, refining processes, fuel injection systems.

-

Common units:

-

Liquids: Barrels per day (bbl/day), gallons per minute (GPM), cubic meters per hour (m³/h)

-

Gases: Standard cubic feet per minute (SCFM), cubic meters per day (m³/day)

-

-

Why it matters: Accurate flow measurements are required to calculate production volumes, allocate costs, and meet environmental and safety regulations.

2. Water and Wastewater Treatment

-

Applications: Municipal water distribution, sewage systems, filtration processes.

-

Common units:

-

Liters per second (L/s), gallons per minute (GPM), cubic meters per hour (m³/h)

-

-

Key concerns: Pressure loss, pipe sizing, treatment flow capacity.

-

Importance: Flow rate governs water treatment dosage, filter sizing, and overall system throughput.

3. HVAC Systems (Heating, Ventilation, and Air Conditioning)

-

Applications: Airflow in ducts, chilled water distribution, fan performance evaluation.

-

Units typically used:

-

Cubic feet per minute (CFM) for air

-

Gallons per minute (GPM) or liters per minute (L/min) for water

-

-

Impact: Proper unit selection ensures thermal comfort, system efficiency, and accurate air balancing.

4. Chemical and Petrochemical Industry

-

Applications: Chemical dosing, reactor feeds, solvent delivery systems.

-

Preferred volumetric flow rate units:

-

Milliliters per minute (mL/min), liters per hour (L/h), or cubic meters per hour (m³/h)

-

-

Precision is vital: Even small flow deviations can affect product quality or safety.

5. Pharmaceutical and Biotech

-

Applications: Sterile fluid delivery, infusion systems, precision dosing.

-

Common units:

-

mL/min, L/min, or custom flow units specific to medical devices

-

-

Importance: Accurate flow rate measurement ensures patient safety and meets strict GMP (Good Manufacturing Practice) standards.

6. Automotive and Aerospace

-

Applications: Fuel injection, lubrication, cooling, aerodynamic testing.

-

Typical units:

-

Cubic centimeters per second (cc/s), liters per hour (L/h), pounds per hour (lb/h for mass)

-

-

Why unit accuracy is key: Even minor flow inconsistencies can affect engine performance or flight safety.

7. Food and Beverage Industry

-

Applications: Flow of milk, syrup, beer, juices in production lines.

-

Units used:

-

L/min, m³/h, or GPM

-

-

Process control: Consistent flow ensures proper mixing, pasteurization, and packaging volumes.

8. Power Generation and Energy

-

Applications: Boiler feedwater, cooling systems, steam distribution.

-

Flow units used:

-

m³/h for water, SCFM for air/steam

-

-

Impact: Flow control affects thermal efficiency, turbine output, and operational safety.

Why Industry-Specific Units Matter

Using the appropriate volumetric flow rate units:

-

Ensures compatibility with legacy equipment and international standards

-

Simplifies regulatory compliance and reporting

-

Helps reduce conversion errors and communication breakdowns between teams or vendors

Unit Conversion Techniques

Given the diversity of volumetric flow rate units used across industries and regions, the ability to accurately convert between units is essential. Whether you’re collaborating on an international project or comparing performance data across different systems, conversions ensure consistency and clarity. This section covers the most common conversion techniques, tools, and practical examples to help you confidently work with any flow rate unit.

1. Understanding the Basics of Unit Conversion

Volumetric flow rate unit conversions are based on known relationships between units. For example:

-

1 cubic meter (m³) = 1,000 liters (L)

-

1 gallon (U.S.) = 3.78541 liters

-

1 cubic foot = 28.3168 liters

-

1 CFM (cubic foot per minute) = 28.3168 L/min

-

1 GPM (U.S.) = 3.78541 L/min

Tip: Always ensure that both volume and time units are appropriately matched (e.g., converting cubic meters per second to liters per minute requires converting both volume and time).

2. Manual Conversion Example

Let’s say you want to convert 100 gallons per minute (GPM) to liters per minute (L/min):

100 GPM×3.78541=378.541 L/min

Or converting 500 CFM to m³/h:

500 CFM×1.699=849.5 m³/h

These types of calculations are straightforward once you memorize or refer to key conversion factors.

3. Common Conversion Factors Table

| From → To | Multiply By | Resulting Unit |

|---|---|---|

| GPM (U.S.) → L/min | 3.78541 | Liters per minute |

| L/min → GPM (U.S.) | 0.264172 | Gallons per minute |

| CFM → m³/h | 1.699 | Cubic meters/hour |

| m³/h → CFM | 0.588578 | Cubic feet/minute |

| m³/s → L/min | 60,000 | Liters per minute |

| L/min → m³/h | 0.06 | Cubic meters/hour |

4. Using Online Calculators and Software Tools

Modern engineering relies heavily on digital tools to eliminate human error and save time. These tools include:

-

Online unit converters: Websites or apps where you can plug in values and instantly convert between volumetric flow rate units

-

Engineering software: Programs like MATLAB, AutoCAD, or PipeFlow Expert often have built-in unit management systems

-

SCADA systems: Supervisory control software often displays real-time flow rates in user-defined units

5. Excel Conversion Example

In Excel, you can use simple formulas to automate conversions. For instance:

= A2 * 3.78541 // Convert GPM to L/min

= B2 / 1000 // Convert L/min to m³/min

This is particularly useful when handling large data sets or trend analysis across different systems using varying volumetric flow rate units.

6. Tips to Avoid Conversion Errors

-

Always double-check time units: A common mistake is converting volume but forgetting to convert time (e.g., seconds to minutes).

-

Use significant figures: Maintain accuracy by not rounding off too early in the calculation.

-

Document unit assumptions: Especially in collaborative or cross-functional teams, always specify what unit is being used.

-

Be aware of U.S. vs. U.K. gallons: They are different (1 UK gal = 4.54609 L).

Volumetric Flow Rate in Engineering Design

In engineering design, the correct use of volumetric flow rate units is more than a matter of preference—it is critical for optimizing system performance, ensuring safety, and maintaining regulatory compliance. Whether designing pipelines, pumps, ventilation systems, or fluid handling components, engineers must accurately calculate and apply volumetric flow rate to ensure the system meets operational requirements.

1. Role in Pipe and Duct Sizing

When fluids move through pipes or air flows through ducts, the volumetric flow rate determines the required cross-sectional area to avoid excessive pressure loss, turbulence, or flow restriction.

-

Q: Volumetric flow rate

-

A: Cross-sectional area

-

v: Fluid velocity

By rearranging this equation, engineers can size pipes and ducts to match expected flow rates using the correct volumetric flow rate units—whether that’s cubic meters per second (m³/s) or cubic feet per minute (CFM).

2. Pump and Valve Sizing

Pumps and control valves are typically rated based on flow capacity, which is expressed using volumetric flow rate units such as GPM (gallons per minute) or L/min (liters per minute). Selecting a pump or valve that is too small can starve the system, while one that’s oversized may lead to inefficiencies, cavitation, or wear.

Key design considerations:

-

Pump flow curves matched with system resistance curves

-

Valve coefficient (Cv or Kv) calculations based on flow rate

-

Compatibility with process conditions and unit standards

3. Impact on System Pressure and Head Loss

Volumetric flow rate is a major factor in calculating pressure drop across piping systems and components. Higher flow rates typically result in increased frictional losses, especially in long or narrow pipes.

Pressure drop calculations rely on:

-

Flow velocity (derived from Q and pipe diameter)

-

Fluid type (viscosity, density)

-

Pipe material and roughness

Engineering tools often ask for input using specific volumetric flow rate units, so consistent use of the correct unit is essential for accurate simulation and modeling.

4. Energy Efficiency and Operating Cost

Optimizing flow rate helps reduce energy consumption:

-

Over-pumping or over-ventilating wastes energy

-

Properly matched flow rates ensure systems run at peak efficiency

-

Engineers use flow data (e.g., in m³/h or L/min) to select energy-efficient motors, blowers, or chillers

Monitoring systems like SCADA or BMS (Building Management Systems) rely on flow sensors outputting data in the appropriate volumetric flow rate units for dashboards and reports.

5. Case Example: Cooling System Design

In a closed-loop chilled water system:

-

Target cooling demand = 100 kW

-

Desired ΔT (temperature difference) = 5°C

-

Using the formula:

Q=ρ⋅cp⋅ΔTPEngineers calculate required volumetric flow rate in L/min or m³/h and size the piping, pump, and heat exchanger accordingly.

Incorrect assumptions about volumetric flow rate units (e.g., using GPM instead of L/min) could lead to design mismatches or underperformance.

6. Compliance and Standards

Various engineering standards specify acceptable flow rates and reporting formats:

-

ASHRAE, API, ISO, and ANSI standards often define flow requirements in specific units

-

Engineering drawings and specs must clearly indicate the volumetric flow rate units to avoid construction errors or miscommunication

By properly integrating volumetric flow rate units into design calculations, engineers can ensure optimized performance, reduced costs, and long-term system reliability. Up next, we’ll discuss the common challenges and pitfalls engineers face when dealing with flow measurement and unit conversions.

Challenges and Pitfalls in Measurement

While volumetric flow rate units are a foundational aspect of fluid measurement, engineers and technicians often encounter challenges that can compromise accuracy and system performance. These issues may stem from incorrect unit usage, environmental conditions, equipment limitations, or lack of calibration. Understanding and avoiding these pitfalls is essential for reliable data and optimal operation.

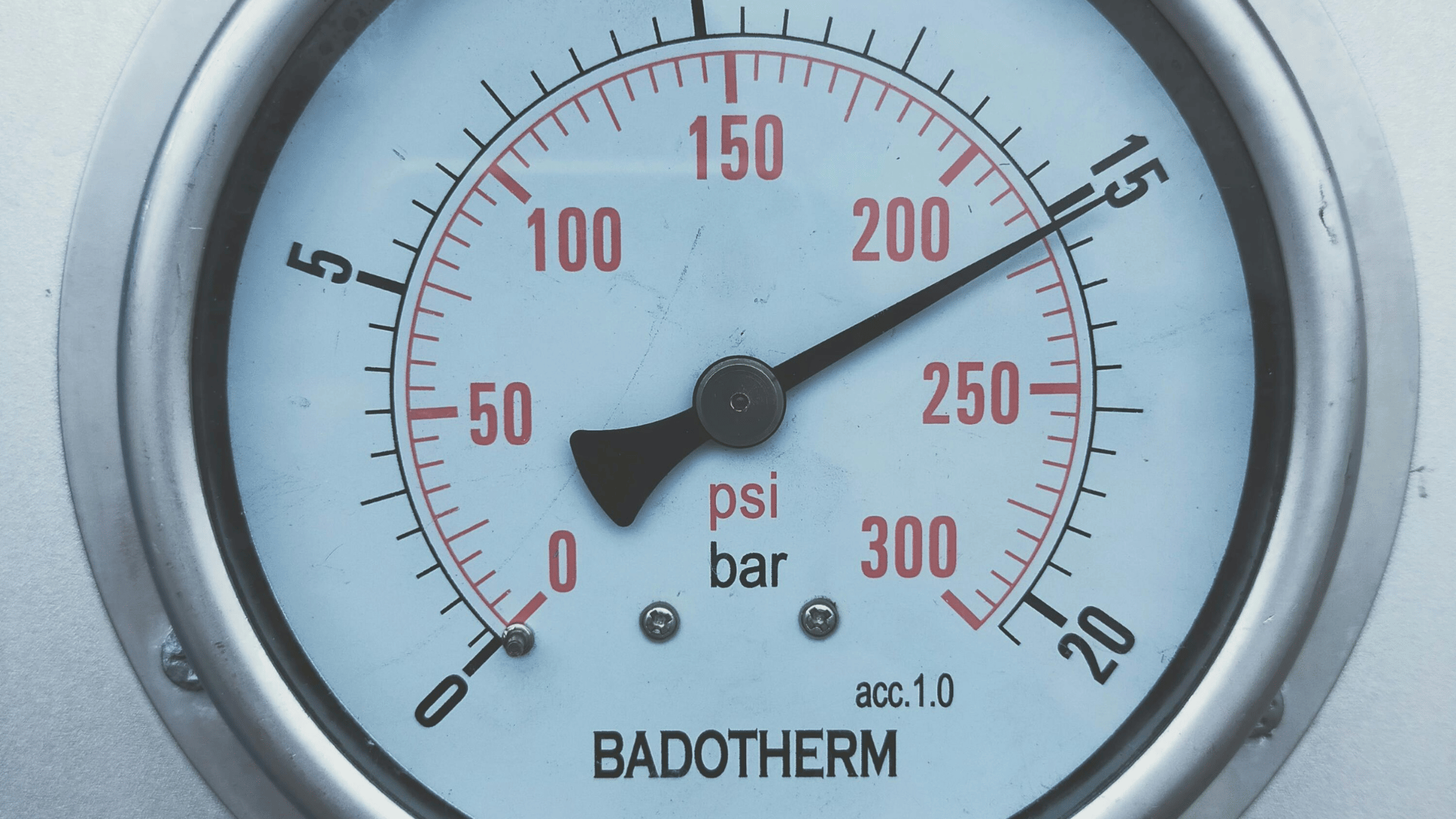

1. Temperature and Pressure Variations

Gases are particularly sensitive to changes in pressure and temperature. Since volumetric flow rate measures volume, and gas volume varies with environmental conditions, readings can be misleading unless corrected.

-

Example: A flow meter may report 100 SCFM (standard cubic feet per minute), which refers to a normalized condition, not actual flow.

-

Solution: Always distinguish between actual and standardized flow when working with gas flow rate units. Use correction factors or temperature/pressure compensation features in instrumentation.

2. Fluid Viscosity and Phase

The viscosity of liquids or the presence of multi-phase flow (liquid + gas or solid) can alter flow dynamics and skew readings.

-

High-viscosity fluids may cause laminar flow, requiring recalibration of flow meters.

-

Multiphase flow (e.g., air bubbles in water) affects accuracy in devices like ultrasonic or turbine meters.

Tip: Choose devices that are designed for your specific fluid type and validate that they support your required volumetric flow rate units.

3. Instrument Calibration and Drift

Even the most precise flow meters require periodic calibration to ensure accuracy.

-

Over time, sensors drift due to wear, fouling, or environmental effects.

-

A 2% error in calibration could mean significant volume discrepancies over time, especially in high-flow industrial systems.

Best practice: Establish a scheduled maintenance and calibration plan aligned with the units your systems report in (e.g., m³/h or GPM).

4. Unit Confusion and Miscommunication

Misinterpreting or mixing up volumetric flow rate units is a common—and costly—error in design and operations.

-

U.S. vs. U.K. Gallon: A U.S. gallon = 3.785 L, but a U.K. gallon = 4.546 L

-

Time base mismatches: Confusing L/min with L/s can lead to 60x errors

Preventive measures:

-

Always document the unit clearly in reports, drawings, and specifications

-

Use automated software tools or calculators that lock input/output units

-

Train personnel on standard unit usage relevant to your industry

5. Incorrect Flow Meter Installation

Improper installation—such as poor alignment, inadequate straight pipe runs, or air pockets—can cause major flow measurement errors, regardless of the volumetric flow rate units.

Common issues:

-

Turbulence caused by valves or elbows near the meter

-

Air entrapment in liquid systems

-

Backflow or pulsating flow in pumps

Tip: Follow the manufacturer’s guidelines for proper meter orientation, placement, and environmental conditions.

6. Human Error in Unit Conversion

Relying on manual conversion without verifying calculations can lead to disastrous results.

-

A misplaced decimal or misapplied conversion factor can cause under- or over-design

-

Repeating calculations without tools increases the risk of compounding errors

Best practice:

-

Use verified conversion software or spreadsheets

-

Always cross-check units across systems and with client requirements

Emerging Trends in Flow Measurement

As industries embrace digital transformation and automation, the measurement of fluid flow is evolving rapidly. These advancements aim to improve accuracy, simplify monitoring, and enhance integration with larger control systems. Many of these innovations also support more dynamic handling and visualization of volumetric flow rate units, making real-time operations more transparent and efficient.

1. Smart Flow Meters and IoT Integration

Modern flow meters are increasingly equipped with smart sensors that connect to the Internet of Things (IoT). These devices collect and transmit flow data continuously, often in configurable volumetric flow rate units, such as GPM, L/min, or m³/h.

Benefits:

-

Remote monitoring of flow systems in real-time

-

Predictive maintenance alerts based on abnormal flow behaviors

-

Reduced human intervention and error

Application examples: Water utilities, oil pipelines, and HVAC systems using IoT-connected ultrasonic or electromagnetic flow meters.

2. Real-Time Analytics and Cloud Dashboards

Advanced flow monitoring systems now feed live data into cloud-based analytics platforms, where users can:

-

Select preferred volumetric flow rate units from dropdown menus

-

Visualize trends, spikes, and anomalies instantly

-

Compare performance across sites or installations

This is particularly valuable for multi-location facilities, process engineers, and energy auditors who need standardization across datasets.

3. Adaptive Flow Control Systems

Intelligent control valves and pumps now respond to changes in flow demand using embedded flow sensors. These systems auto-adjust based on feedback, ensuring consistent delivery regardless of load.

Key features:

-

Self-tuning PID loops that stabilize flow

-

Integration with SCADA or PLC systems

-

On-screen unit toggling (e.g., display switching between L/min and m³/h)

Such systems are being adopted in smart manufacturing, district energy systems, and precision agriculture.

4. Mobile Apps and Wireless Calibration Tools

Many modern flow measurement systems support mobile app calibration and monitoring. Field technicians can connect wirelessly to a flow meter, verify readings, or recalibrate based on real-time conditions—all while viewing flow in selectable volumetric flow rate units.

Advantages:

-

Faster setup and maintenance

-

Reduced reliance on bulky equipment

-

Seamless unit conversion without manual calculation

5. Standardization Across International Projects

As global collaboration becomes the norm, industry organizations like ISO, ASME, API, and IEC are pushing for standardized volumetric flow rate units to reduce miscommunication and error.

Emerging initiatives include:

-

Digital twin models using unified data formats

-

API-compliant flow meter certifications

-

Industry 4.0 platforms aligning flow data with digital standards

6. AI-Driven Flow Diagnostics

Artificial Intelligence (AI) is being integrated into flow systems to detect:

-

Calibration drift

-

Blockages or leaks

-

Inefficient flow patterns based on historical data

These AI systems can work with flow data across any volumetric flow rate units, normalize them, and present alerts or optimization recommendations.

Future Outlook

The trend is clear: volumetric flow measurement is shifting toward automated, accurate, and intelligent systems with seamless support for global units. As instrumentation becomes smarter, the choice of volumetric flow rate units will increasingly become a simple, software-level configuration—making flow data easier to access, interpret, and act upon.

Conclusion

Understanding and applying the correct volumetric flow rate units is essential across a wide spectrum of engineering, industrial, and scientific disciplines. From calculating precise flow rates in pharmaceutical manufacturing to optimizing HVAC systems or designing large-scale oil pipelines, accurate measurement ensures both efficiency and safety.

Throughout this guide, we explored:

-

The definition and principles behind volumetric flow rate

-

A breakdown of common volumetric flow rate units in both metric and imperial systems

-

How to measure flow accurately using various instruments

-

Industry-specific applications and the importance of using consistent units

-

Techniques for converting between units to avoid errors

-

Integration of flow rate into engineering design calculations

-

Common challenges in flow measurement and how to avoid them

-

Emerging technologies that are reshaping how we manage and analyze flow data

The key takeaway is this: mastering volumetric flow rate units isn’t just about knowing how to read a gauge or convert from GPM to L/min. It’s about making informed design decisions, ensuring compliance, optimizing performance, and enabling innovation in an increasingly connected and data-driven world.

As technologies continue to evolve, the way we measure and interpret flow will become more intuitive and precise. But no matter how advanced the tools become, a solid understanding of volumetric flow rate units will always remain at the heart of effective fluid system management.