The bar unit is one of the most commonly used non-SI units for measuring pressure in various fields such as engineering, meteorology, automotive systems, and industrial manufacturing. Although the bar is not part of the International System of Units (SI), it remains widely used across the globe due to its practicality and ease of understanding. Defined as 100,000 pascals, the bar unit provides a convenient way to express atmospheric and gauge pressures without resorting to excessively large or small numbers.

Understanding the bar unit is essential for anyone working with pressure-related applications. From measuring the pressure inside a car tire to evaluating the forces acting on deep-sea submersibles, the bar unit helps engineers, technicians, and scientists express data in a clear and standardized form. While alternative units like the pascal (Pa), pounds per square inch (psi), or atmospheres (atm) are also in use, the bar unit strikes a balance between simplicity and accuracy, especially in metric-based systems.

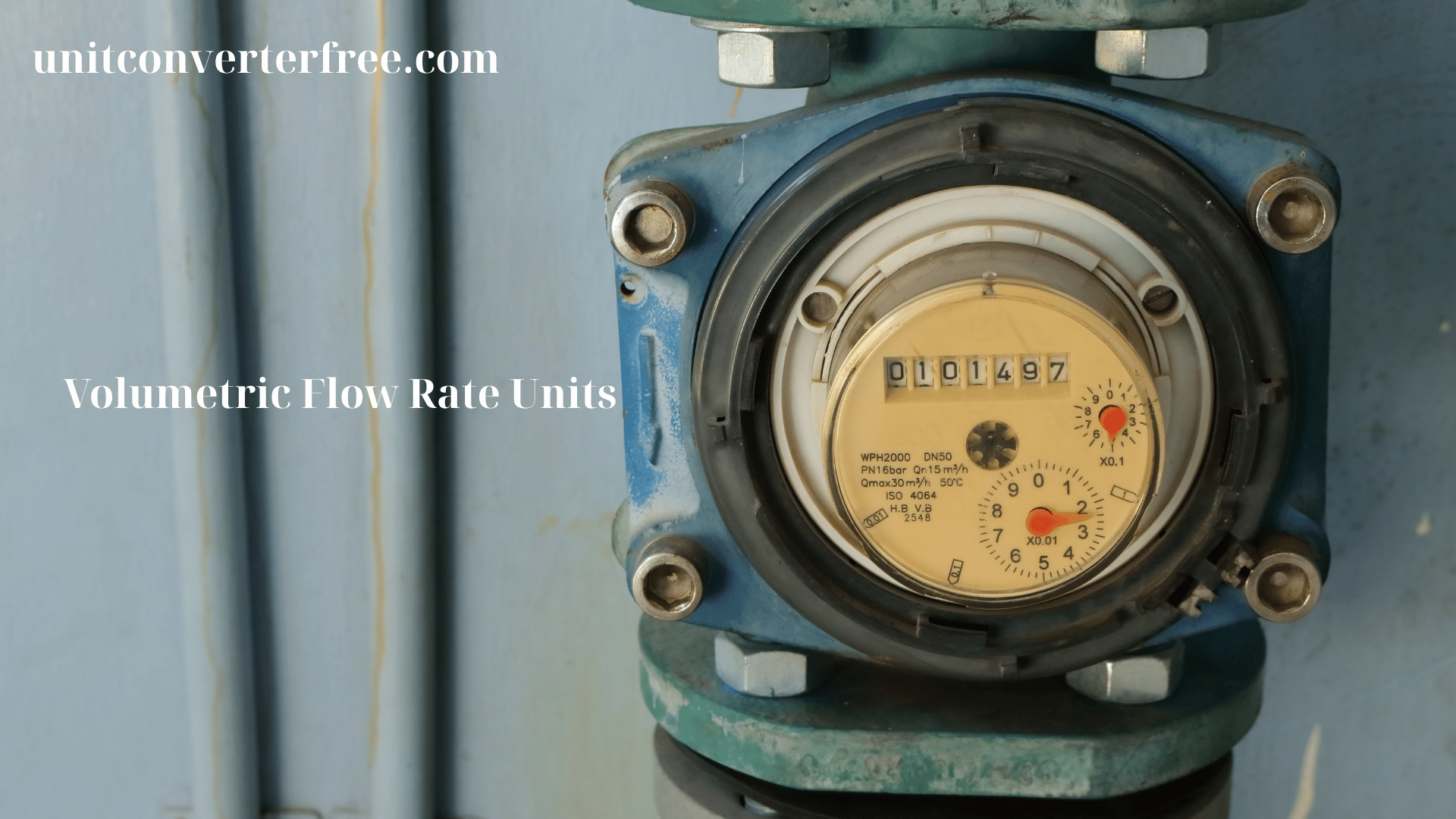

The widespread use of the bar unit can be seen in pressure gauges, technical documentation, and even weather reports, where millibar (mbar) is commonly used to describe atmospheric pressure. In industries such as oil and gas, pneumatic systems, and hydraulic machinery, the bar unit is frequently chosen for system specifications and safety calculations. This level of ubiquity makes it important for professionals and students alike to understand its meaning, conversions, and practical significance.

The bar unit originated from the metric system and gained traction during the 20th century as a practical solution to represent pressure without needing to work with very large numbers in pascals. One bar is almost equivalent to atmospheric pressure at sea level (1.013 bar ≈ 1 atm), making it intuitive for many real-world applications. Its definition aligns closely with human experience—such as the pressure we feel at sea level—which is why the bar remains entrenched in multiple global industries.

Despite its usefulness, the bar unit is technically classified as a non-SI unit, which has led to some debate about its future in scientific and academic contexts. However, it remains legally accepted for use with the SI and continues to appear in product datasheets, industrial equipment, and regulatory documents. Many international standards, including those from ISO and DIN, permit or mention the bar unit, further solidifying its practical utility.

In this comprehensive article, we will explore everything you need to know about the bar unit—from its definition and historical background to its applications, conversions, and relevance in today’s industries. We’ll cover how the bar unit compares to other pressure units, why it continues to be used despite being non-SI, and how it can be converted easily for both academic and industrial use. You’ll also find real-world examples, conversion tables, and frequently asked questions to help deepen your understanding.

Whether you’re a student learning about pressure measurements for the first time, a professional dealing with pressure instruments, or someone curious about units of measurement, this guide to the bar is designed to provide clarity and practical insight. By the end of this article, you’ll have a strong grasp of how and where the bar is applied, and why it still holds a prominent place in pressure measurement around the world.

What Is the Bar Unit?

The bar unit is a metric-derived unit of pressure, defined as exactly 100,000 pascals (Pa). This means that one bar is equivalent to a force of 100,000 newtons per square meter. Though not part of the International System of Units (SI), the bar unit is widely used in many fields due to its practical size and simplicity.

To understand the bar unit better, it helps to compare it with both SI and non-SI pressure units. The official SI unit of pressure is the pascal (Pa), named after Blaise Pascal, a French mathematician and physicist. While the pascal is suitable for scientific accuracy, it is often too small for many practical purposes. For instance, the average atmospheric pressure at sea level is about 101,325 pascals, which can be cumbersome to work with in everyday contexts. The bar unit, at exactly 100,000 pascals, offers a more intuitive figure for engineers and meteorologists alike.

Here’s how the bar unit compares with other commonly used pressure units:

| Unit | Equivalent in Bars |

|---|---|

| 1 bar | 100,000 pascals (Pa) |

| 1 atmosphere (atm) | ≈ 1.01325 bar |

| 1 psi | ≈ 0.0689476 bar |

| 1 mmHg | ≈ 0.00133322 bar |

| 1 torr | ≈ 0.00133322 bar |

| 1 kilopascal (kPa) | 0.01 bar |

This table shows that the bar serves as a convenient “middle ground” between very small units like the pascal and larger imperial units like psi. It is especially favored in contexts where atmospheric pressure or moderate industrial pressure levels are being measured.

Why Is the Bar Unit Not an SI Unit?

Despite being based on the metric system and aligning with SI principles, the bar unit is not officially recognized as part of the SI. This is primarily because the pascal (Pa) already fulfills the SI requirement for a pressure unit. As such, international bodies like the Bureau International des Poids et Mesures (BIPM) encourage the exclusive use of SI units in scientific documentation.

However, the bar unit is still legally accepted for use with the SI, meaning it is permissible in technical documents, engineering standards, and industry specifications, particularly where practicality is prioritized over strict conformity.

Submultiples and Multiples of the Bar Unit

The bar can be conveniently scaled up or down to suit various measurement needs:

-

Millibar (mbar or mb): 1 bar = 1,000 millibars

-

Commonly used in meteorology to report atmospheric pressure.

-

-

Kilobar (kbar): 1 kbar = 1,000 bars

-

Often used in geology and materials science for extremely high pressures.

-

For example, average atmospheric pressure at sea level is 1,013.25 mbar, which is very close to 1.01325 bar—highlighting the bar unit’s intuitive usefulness in expressing common pressures.

Scientific and Practical Use Cases

-

Engineering: Hydraulic and pneumatic systems often use the bar unit to express system pressures. For instance, a typical car tire may require inflation to 2.2 bar, which is both easy to read and convert.

-

Weather Forecasting: Weather stations and meteorological maps frequently use millibar to indicate atmospheric pressure patterns.

-

Manufacturing: In industrial equipment and instrumentation, pressure gauges and transducers are often calibrated in bars or millibars.

-

Diving and Aviation: These industries utilize the bar unit to represent absolute or gauge pressures, such as underwater depth pressure or cabin pressure.

In summary, the bar unit is a pressure measurement tool that balances clarity, usability, and wide-ranging application. Even though it is not part of the formal SI system, it continues to be an essential unit in engineering, meteorology, and industrial environments. Its fixed equivalence of 100,000 pascals makes the bar unit easy to convert, easy to visualize, and simple to integrate into real-world measurements. As you explore further into pressure-related topics, understanding the bar unit will provide a solid foundation for interpreting and comparing values across different systems.

Mathematical Conversions Involving the Bar Unit

Understanding how to convert the bar unit into other pressure units is essential for scientists, engineers, and technicians working across various industries. Since pressure can be measured in several unit systems depending on the country, application, or industry, accurate and efficient conversions are necessary to ensure data consistency and operational safety.

The bar unit, defined as exactly 100,000 pascals, serves as a convenient reference point for conversion to both SI and non-SI units. Below, we explore the most common pressure conversions and how to calculate them.

1. Bar Unit to Pascal (Pa) and Kilopascal (kPa)

Since 1 bar = 100,000 pascals:

-

Formula:

Pressure (Pa)=Pressure (bar)×100,000 -

Example:

Convert 2.5 bar to pascals:

2.5bar×100,000=250,000Pa

To convert to kilopascals (kPa):

-

1 bar = 100 kPa

Pressure (kPa)=Pressure (bar)×100

2. Bar Unit to Atmosphere (atm)

-

1 bar ≈ 0.986923 atm

-

Formula:

Pressure (atm)=Pressure (bar)×0.986923 -

Example:

Convert 3 bar to atm:

3×0.986923≈2.9608atm

This makes the bar especially intuitive for comparing with atmospheric pressure, since 1 bar is nearly equivalent to 1 atm.

3. Bar Unit to PSI (Pounds per Square Inch)

-

1 bar ≈ 14.5038 psi

-

Formula:

Pressure (psi)=Pressure (bar)×14.5038 -

Example:

Convert 1.2 bar to psi:

1.2×14.5038≈17.4046psi

In the United States, psi is the dominant pressure unit. Converting between bar unit and psi is vital for international compatibility.

4. Bar Unit to Torr and mmHg

-

1 bar ≈ 750.062 torr

-

1 bar ≈ 750.062 mmHg

-

Formula:

Pressure (torr)=Pressure (bar)×750.062 -

Example:

Convert 0.5 bar to torr:

0.5×750.062=375.031torr

Since torr and mmHg are interchangeable, the bar unit can be used to estimate medical or scientific vacuum pressures when necessary.

5. Bar Unit to Other Common Units (Quick Reference Table)

| From (Bar) | To (Unit) | Conversion Factor | Result (1 bar = …) |

|---|---|---|---|

| bar | Pa | × 100,000 | 100,000 Pa |

| bar | kPa | × 100 | 100 kPa |

| bar | atm | × 0.986923 | 0.986923 atm |

| bar | psi | × 14.5038 | 14.5038 psi |

| bar | torr | × 750.062 | 750.062 torr |

| bar | mmHg | × 750.062 | 750.062 mmHg |

6. Reverse Conversions (Back to Bar Unit)

Sometimes, it’s necessary to convert from other units to the bar unit. Here are a few reverse formulas:

-

From Pa to bar:

Pressure (bar)=Pressure (Pa)÷100,000 -

From atm to bar:

Pressure (bar)=Pressure (atm)÷0.986923 -

From psi to bar:

Pressure (bar)=Pressure (psi)÷14.5038

These reverse equations make it simple to standardize international specifications and ensure compatibility between systems that use different pressure units.

7. Online Tools and Calculators for Bar Unit Conversion

For convenience, many engineers and technicians use digital calculators or apps that can handle bar unit conversions. These tools allow rapid switching between units, often supporting batch conversion for data sets. Examples include:

-

Google’s built-in unit converter

-

Wolfram Alpha

-

Mobile apps for iOS and Android

-

Excel conversion formulas

Mathematical conversions involving the bar unit are straightforward and essential for cross-functional work in science, engineering, weather forecasting, and industry. Since the bar unit is close to atmospheric pressure, it offers a highly intuitive and practical way to communicate and calculate pressure values. Mastering these conversions ensures accuracy, safety, and clarity in both technical documentation and real-world operations.

Applications of the Bar Unit in Different Industries

The bar plays a critical role in numerous industries that require accurate and consistent pressure measurements. From monitoring fuel injection in vehicles to assessing deep-sea pressure on subsea equipment, the bar serves as a universally recognized and widely used metric for pressure-related operations. Despite being a non-SI unit, its usability and ease of understanding have made it a standard across many sectors.

Below are the most notable industries where the bar unit is integral to day-to-day operations.

1. Automotive Industry

In automotive engineering, the bar unit is frequently used to measure tire pressure, turbocharger boost, fuel injection pressure, and brake system performance.

-

Tire pressure: Most European cars indicate tire pressures in bars. For instance, a recommended tire pressure might be 2.3 bar, which equals approximately 33.36 psi.

-

Fuel systems: Modern fuel injection systems operate under high pressure—often between 2 to 6 bar—and these values are critical to engine performance and efficiency.

-

Turbochargers: Boost pressure is typically expressed in bars, with performance tuning and diagnostics relying on precise bar unit readings.

The bar unit is preferred in this sector for its metric compatibility and straightforward correlation with component specifications.

2. Oil and Gas Industry

The oil and gas sector operates under extreme pressure conditions, making the bar unit essential for:

-

Pipeline pressure monitoring

-

Wellhead pressure management

-

Blowout preventer (BOP) systems

-

Gas compressors and separators

In these high-risk environments, engineers may measure operating pressures from 10 bar up to 700 bar or more. The bar unit is especially valuable in European and offshore applications, where metric-based standards dominate.

Moreover, many data sheets, safety documents, and international standards (such as API and ISO) allow or reference the bar unit, enabling smooth integration with global engineering practices.

3. Aerospace and Aviation

In aerospace, the bar unit is used for:

-

Cabin pressurization systems

-

Fuel tank pressure

-

Environmental control systems

Cabin pressure is often maintained around 0.8 bar (about 11.6 psi) to ensure passenger comfort and safety. The use of the bar unit in such systems allows technicians to calibrate equipment with high precision.

In jet propulsion systems, pressure data expressed in bar unit ensures accurate combustion chamber pressure control, affecting thrust output and engine efficiency.

4. Meteorology and Atmospheric Sciences

The bar unit—especially its subunit, the millibar (mbar)—has long been the standard for measuring atmospheric pressure.

-

Sea-level pressure: Often cited as 1013.25 mbar (≈ 1.013 bar), this benchmark is used worldwide in weather forecasting.

-

Weather maps and reports: Isobars are typically labeled in millibars to indicate zones of high and low pressure.

-

Altitude measurement: Barometric altimeters measure atmospheric pressure in bar units, converting it to altitude data in aviation and meteorology.

The bar unit’s proximity to atmospheric conditions makes it ideal for environmental monitoring and meteorological analysis.

5. Hydraulics and Pneumatics

The design and control of hydraulic and pneumatic systems rely heavily on the bar. Common applications include:

-

Hydraulic presses and cylinders

-

Air compressors

-

Hydraulic steering systems

-

Actuators in automation

Standard operating ranges are between 2 to 350 bar, depending on system requirements. For instance, industrial hydraulic systems often work at 100 to 250 bar, while specialized heavy equipment might exceed 400 bar.

Instrumentation is often marked in bar units for both gauge pressure and safety testing.

6. Medical and Healthcare Industry

In healthcare, the bar unit appears in several types of equipment that involve gas delivery or pressure control:

-

Oxygen tanks: These are typically pressurized to 150 to 200 bar, with regulators calibrated in bars.

-

Anesthesia machines: Use precise bar unit control to deliver correct gas mixtures.

-

Hyperbaric chambers: Measure therapy pressures in bars, often reaching 2 to 3 bar to simulate deeper underwater conditions.

Here, the bar unit supports both safety and clinical accuracy.

7. Manufacturing and Industrial Testing

Manufacturing plants use the bar unit in:

-

Leak testing

-

Pressure vessels

-

Boiler monitoring

-

Material forming equipment (like isostatic presses)

For example, leak tests on pipelines or valves may be conducted at 1.5× operating pressure, expressed in bar unit to ensure consistency with design documentation. Boiler systems are also monitored using pressure gauges marked in bars to maintain safe steam generation.

8. Diving and Subsea Engineering

The bar unit is crucial in diving and subsea operations:

-

Scuba tanks: Typically pressurized to 200–300 bar

-

Depth estimation: Every 10 meters of water depth adds roughly 1 bar of pressure

-

ROV (Remotely Operated Vehicle) equipment: Calibrated using bar unit for pressure resistance testing

Divers and engineers rely on the bar unit for planning dives, ensuring decompression safety, and configuring equipment to withstand hydrostatic forces.

9. Laboratory and Research Applications

Research environments often use the bar unit for:

-

Chemical reactor pressure monitoring

-

Vacuum systems

-

High-pressure testing chambers

While pascals may be used in high-precision academic settings, many laboratory instruments are still calibrated in bar units for practical readability.

The bar unit is more than just a pressure measurement tool—it is a vital standard across countless industries. Whether used in tire gauges, hydraulic presses, weather forecasts, or diving tanks, the bar unit provides a practical and universally understood way to quantify pressure. Its compatibility with the metric system and intuitive relationship to atmospheric conditions make it a go-to unit in both engineering and everyday applications.

Even though it’s technically non-SI, the bar unit remains a trusted and widely adopted standard in global industry. Its continued use across disciplines underscores its versatility, ease of understanding, and relevance in modern measurement systems.

Bar Unit in Engineering Design and Calculations

In engineering disciplines, pressure is a foundational concept that directly influences safety, efficiency, and system functionality. The bar unit is widely adopted in design calculations across mechanical, civil, chemical, and process engineering because of its intuitive scale and compatibility with the metric system. Whether it’s determining the wall thickness of a pressure vessel or sizing a hydraulic pump, the bar unit helps engineers make accurate, practical decisions.

1. Use of the Bar Unit in Pressure Vessel Design

One of the most critical applications of the bar unit in engineering is in the design of pressure vessels. Engineers calculate the internal pressure of the vessel—often measured in bars—and apply safety factors to ensure structural integrity under all expected operating conditions.

Example:

-

Design Pressure = 6 bar (gauge)

-

Allowable Stress of material = known from material standards

-

Using the formula:

t=2⋅σ⋅E−1.2PP⋅Dwhere:

-

t = required wall thickness -

P = internal pressure in bar (converted to Pa if needed) -

D = inner diameter -

σ = allowable stress -

E = weld efficiency

-

Here, the bar unit simplifies initial inputs before converting to pascals as required by SI calculations.

2. Bar Unit in Fluid Dynamics and Piping Systems

In fluid systems, engineers use the bar unit to assess pressure drop across valves, elbows, filters, and long pipelines.

-

Bernoulli’s equation, Darcy-Weisbach, and Hazen-Williams formulas all include pressure as a key variable.

-

Pressure loss is commonly measured in bars, especially in industrial reports and design specifications.

Example:

If the pump inlet pressure is 3.5 bar and the outlet is 7 bar, the system must handle a 3.5 bar pressure differential. Engineers use this to size pipe diameters, wall thickness, and valve types.

3. Chemical Engineering Applications

In chemical plants and refineries, pressure levels in reactors, distillation columns, and separators are monitored and regulated using the bar unit.

-

Many process simulators (like Aspen Plus or HYSYS) accept inputs in bar or kilopascal.

-

Reaction kinetics and phase equilibrium calculations often rely on pressure expressed in bar units, especially when considering gas behavior or vapor-liquid equilibria.

Engineers design safety relief systems and control loops with bar-based setpoints, ensuring critical equipment stays within its operating limits.

4. Structural Load and Stress Calculations

Pressure loads on walls, floors, tanks, and submerged structures are often given in bars. In these calculations, the bar unit helps:

-

Convert pressure into force per area (1 bar = 100,000 N/m²)

-

Analyze stress and deformation using FEA (Finite Element Analysis)

-

Evaluate soil pressure against retaining walls or tunnel linings

Civil engineers often refer to soil pressure in bars to simplify interpretation and to align with geotechnical reports.

5. Instrument Calibration and System Testing

When calibrating instruments such as pressure gauges, transducers, and control valves, engineers often use a bar unit reference.

-

Test benches and calibration certificates frequently list values in bar.

-

Bar-based readings reduce the risk of confusion when aligning field measurements with documentation.

Routine hydrostatic and pneumatic pressure testing is also conducted using values in bar unit, ensuring consistency across maintenance teams and inspection reports.

6. Thermodynamics and Energy Conversion

Thermodynamic cycles—such as Rankine, Brayton, and refrigeration cycles—heavily rely on pressure readings. In practical engineering applications:

-

Boiler pressure: 10–160 bar

-

Condenser pressure: < 1 bar

-

Compressor discharge: 2–15 bar

Cycle efficiency, enthalpy changes, and work done calculations use bar data from real-world equipment like turbines, compressors, and condensers.

In the world of engineering, precision and clarity are non-negotiable. The bar provides both. From early conceptual designs to final performance testing, the bar unit simplifies calculations, enhances communication between teams, and ensures alignment with international documentation. Despite being a non-SI unit, its scale and relevance make it a mainstay in pressure-related calculations across virtually every engineering field.

Whether you’re an engineer building an offshore platform, refining a chemical reactor, or optimizing a building’s HVAC system, understanding and applying the bar unit is essential to delivering safe and effective solutions.

Tools and Instruments That Use the Bar Unit

The bar unit is a standard scale used in various tools and instruments designed to measure, monitor, and control pressure. These instruments are used across industries such as automotive, oil and gas, manufacturing, and laboratory testing. Engineers, technicians, and operators frequently interact with these tools to ensure system safety, performance optimization, and regulatory compliance.

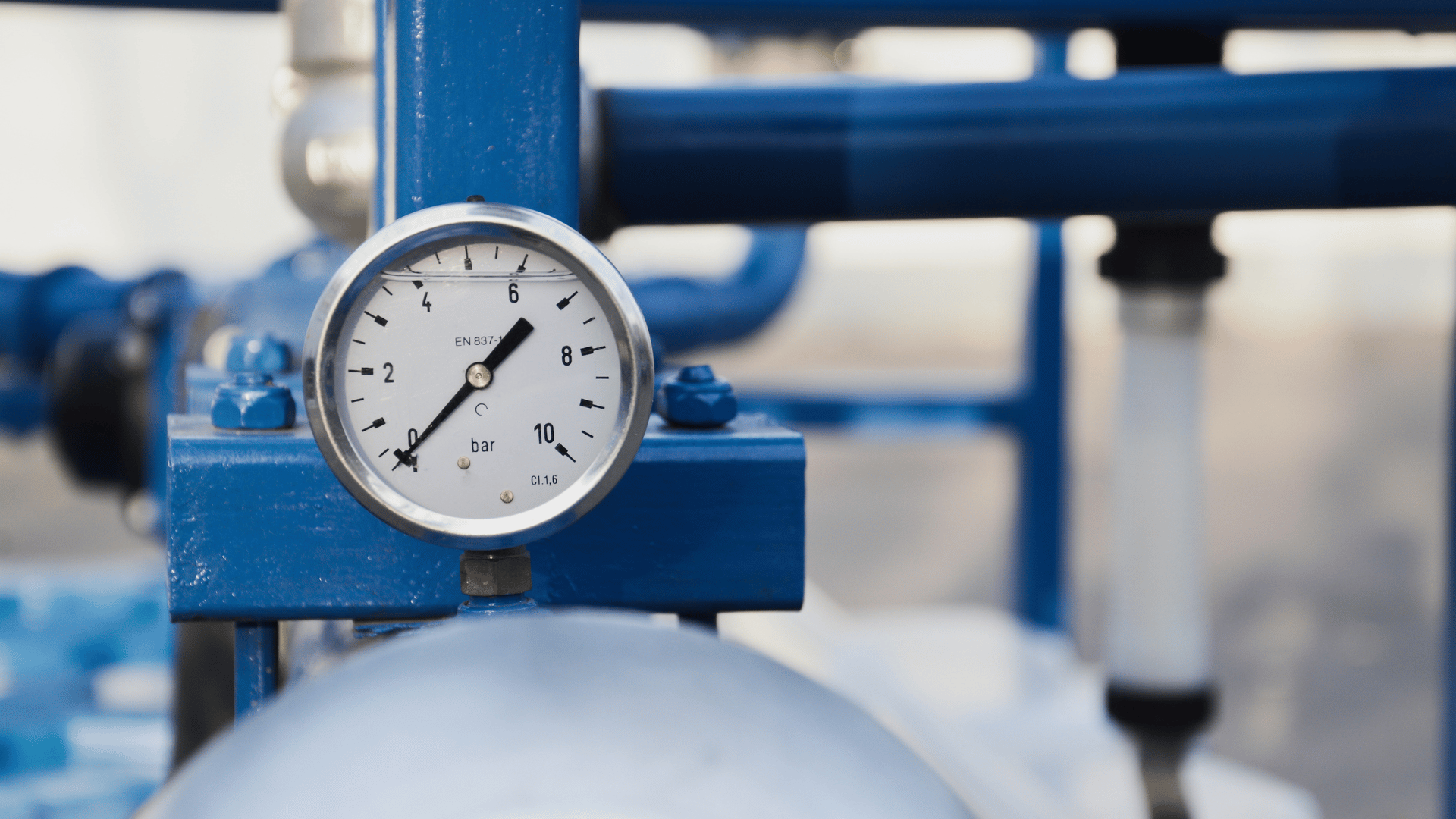

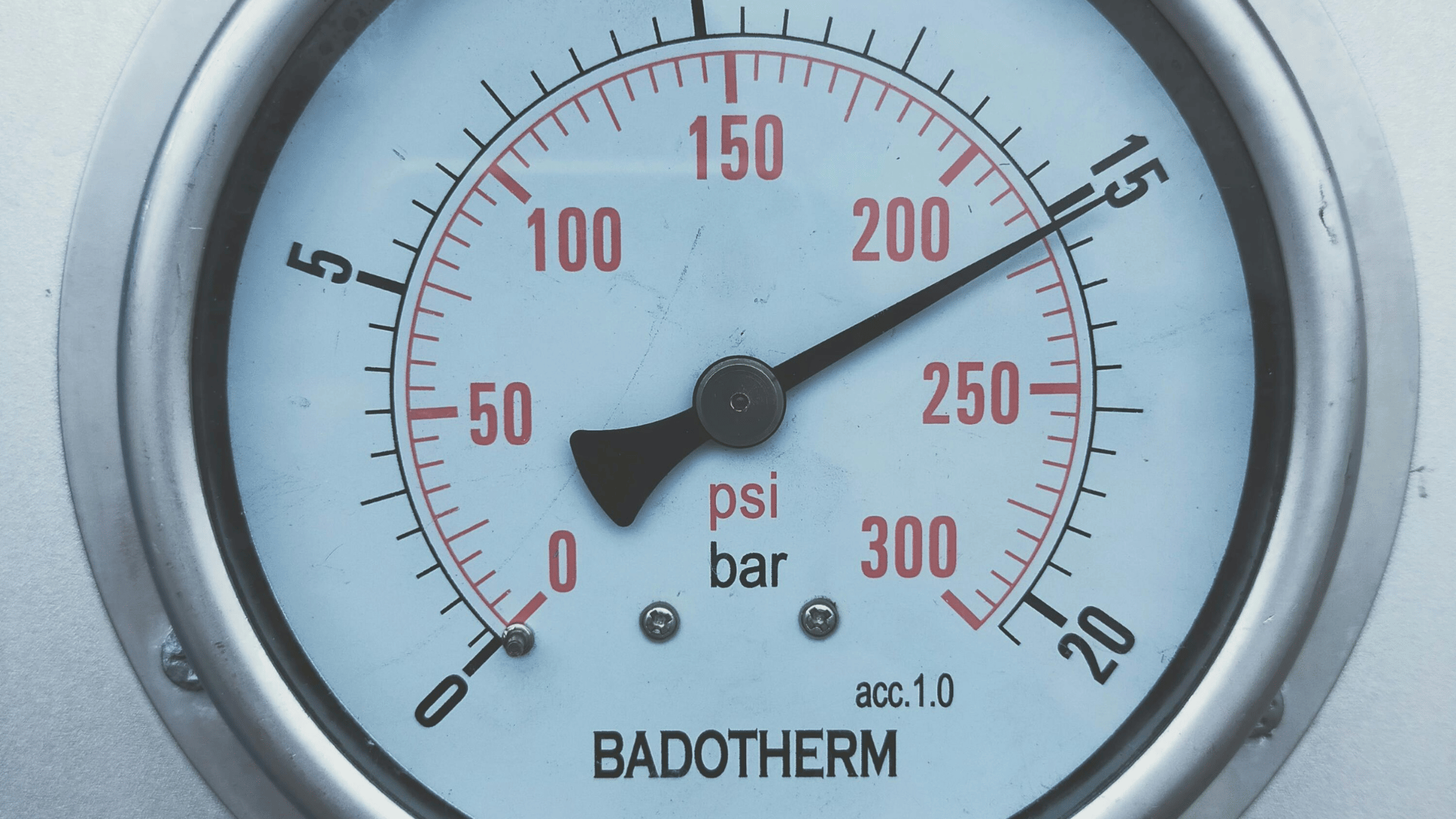

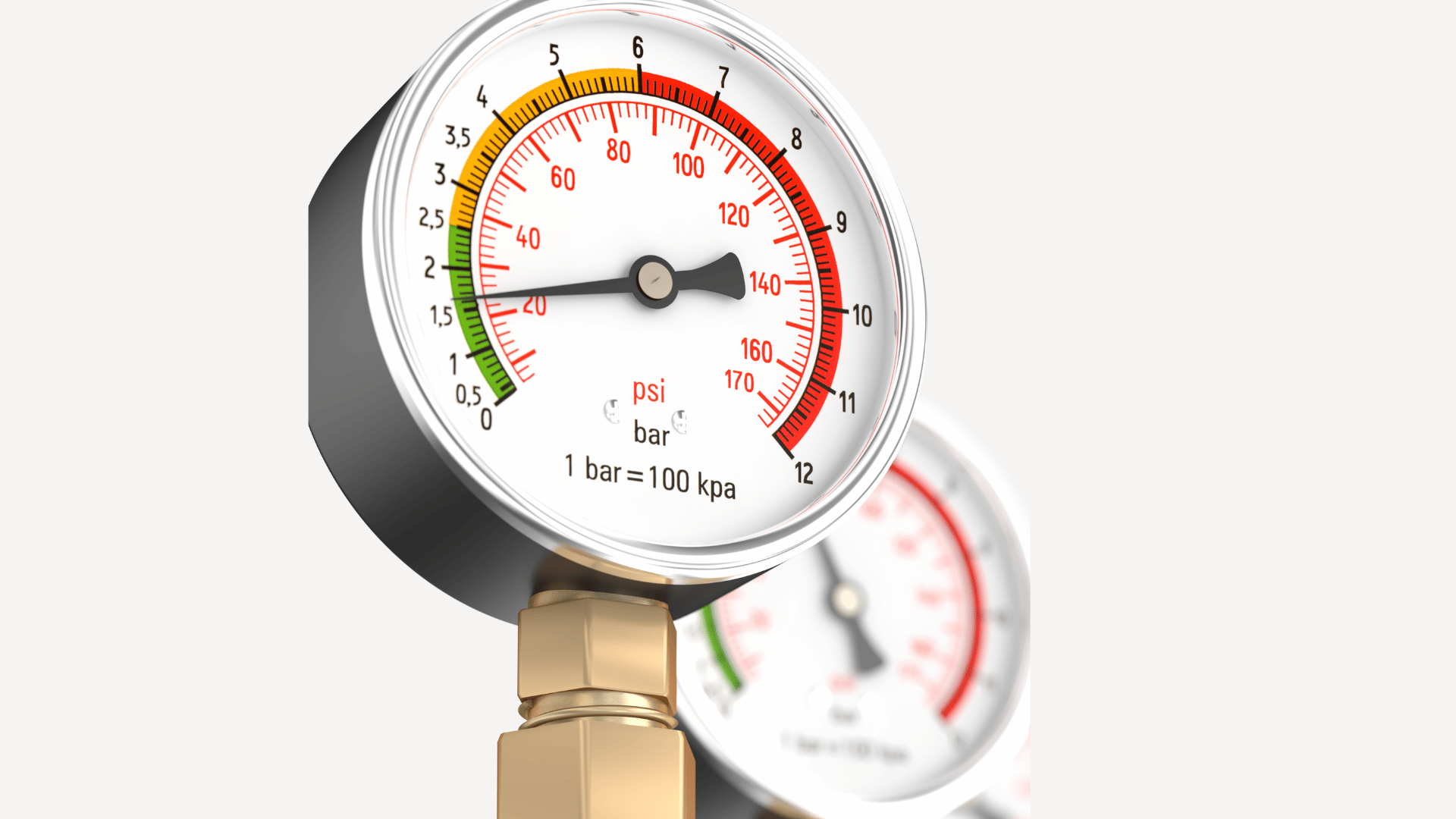

1. Pressure Gauges

Perhaps the most common tool using the bar unit is the analog or digital pressure gauge. These instruments are mounted on pipelines, tanks, hydraulic systems, and gas cylinders.

-

Analog gauges display pressure on a dial, often with bar and psi scales.

-

Digital pressure gauges offer precise bar readings with configurable units and electronic outputs for data logging or alarms.

In industrial environments, pressure gauges typically measure ranges from 0 to 400 bar, depending on system requirements.

2. Pressure Transducers and Sensors

Pressure transducers convert pressure into an electrical signal, which can be monitored by control systems such as PLCs or DCS platforms. These sensors often provide readouts in bar unit or convert it internally before transmission.

Applications include:

-

Monitoring fuel injection pressure in engines

-

Tracking real-time hydraulic pressure

-

Measuring barometric pressure in climate systems

Accuracy, calibration range, and environmental resistance are all tuned to the bar unit as the core pressure metric.

3. Tire Pressure Monitors (TPMS)

In automotive systems, Tire Pressure Monitoring Systems (TPMS) alert drivers when tire pressure drops below the recommended range, usually expressed in bars.

-

Example: A typical warning may appear when tire pressure drops below 1.8 bar.

-

Most European and Asian vehicles display tire pressure in the bar unit, while U.S. vehicles often use psi.

Digital TPMS tools used in garages for service diagnostics can be configured to display in bar unit as default.

4. Barometers

In meteorology, barometers are instruments specifically designed to measure atmospheric pressure. While many barometers use millibars (mbar), the underlying system is based on the bar unit.

-

Digital barometers often allow switching between mbar, bar, and hPa.

-

Barometric pressure helps predict weather patterns, altitude, and storm development.

5. Pressure Calibrators

Calibrators are used in quality control and laboratory environments to verify and fine-tune the accuracy of pressure-measuring instruments.

-

These devices generate known pressure levels in bar units, allowing technicians to compare readings.

-

Calibration documentation and certification usually reference the bar unit to maintain consistency with European and ISO standards.

6. Dive Computers and Gauges

In scuba diving, depth gauges and dive computers use the bar unit to display absolute pressure underwater.

-

At sea level: 1 bar

-

At 10 meters depth: 2 bar (1 bar atmospheric + 1 bar water pressure)

These instruments help divers manage decompression stops and avoid barotrauma.

Differences Between Bar, mbar, and kbar

While the bar unit is commonly used in engineering and industry, its scaled forms—millibar (mbar) and kilobar (kbar)—serve specific applications where finer or much greater pressures must be measured. Understanding the differences between bar, mbar, and kbar is essential for interpreting technical data correctly and selecting the right measurement scale for each context.

1. The Bar Unit (bar)

The bar unit is defined as exactly 100,000 pascals (Pa) and is typically used to measure moderate pressures in everyday industrial and mechanical applications. It offers a convenient middle ground between very large and very small units.

Common uses of the bar unit:

-

Tire pressure (e.g., 2.2 bar)

-

Hydraulic systems (up to 400 bar)

-

Weather forecasts (converted from mbar)

-

Scuba diving depth pressure (1 bar ≈ 10 meters underwater)

The bar unit simplifies communication in industries where pressure frequently operates in ranges close to atmospheric pressure or higher.

2. Millibar (mbar)

The millibar, or mbar, is equal to 1/1000 of a bar, or 100 pascals:

1mbar=0.001bar

The millibar is still widely used in meteorology and barometric measurements, despite increasing adoption of hectopascals (hPa), which are numerically equivalent.

Example use:

-

Standard sea-level atmospheric pressure = 1013.25 mbar

-

Weather maps display isobars (lines of equal pressure) in millibars

Meteorologists prefer the mbar or hPa for its readability when reporting air pressure fluctuations and storm systems.

3. Kilobar (kbar)

The kilobar, or kbar, is equal to 1,000 bars, or 100,000,000 pascals (100 MPa):

1kbar=1,000bar

This unit is used in high-pressure physics, geophysics, material science, and explosives research where extremely high pressures are involved.

Example use:

-

Laboratory studies of rock formation under the Earth’s crust

-

Compression testing of new materials

-

Shock wave and detonation experiments

Because the bar unit becomes numerically unwieldy at high values, switching to kbar simplifies representation and improves clarity in specialized scientific documentation.

4. Summary Table: Bar vs. mbar vs. kbar

| Unit | Value in Bar Unit | Value in Pascals (Pa) | Common Use Cases |

|---|---|---|---|

| mbar | 0.001 bar | 100 Pa | Meteorology, barometric pressure readings |

| bar | 1 bar | 100,000 Pa | Engineering, automotive, diving, industrial |

| kbar | 1,000 bar | 100,000,000 Pa | Geophysics, high-pressure material testing |

While all three units—bar, mbar, and kbar—are derived from the bar unit, they serve vastly different needs. The bar unit is perfect for general industrial and mechanical pressures. The mbar allows precise atmospheric readings, and the kbar provides an efficient way to measure extreme conditions. Understanding these differences ensures accurate pressure interpretation across various technical fields and helps prevent costly errors due to miscommunication.

Usage of Bar Unit in Global Context

The bar unit enjoys widespread acceptance and use across many countries and industries, particularly those following or influenced by the metric system. Although it is not an official SI unit, the bar unit is legally accepted for use alongside SI units and is often the preferred unit of pressure in practical and commercial applications around the world.

1. Europe and the Metric-Adopting World

In much of Europe, the bar unit is a standard measurement for pressure in automotive systems, industrial machinery, HVAC equipment, and public utilities. European Union regulations often permit the use of the bar unit in technical and commercial documentation, especially where its simplicity benefits end users.

Examples:

-

Germany: Widely uses the bar unit for pressure sensors, tire inflation systems, and hydraulic equipment.

-

France and Italy: Gas cylinders and pressure regulators are typically labeled in bars.

-

Scandinavia: Weather forecasts often express atmospheric pressure in millibars, directly tied to the bar unit.

In many metric-adopting nations outside Europe—such as India, Australia, South Africa, and parts of South America—the bar unit is used interchangeably with SI pressure units depending on the industry or legacy practice.

2. The United States and Canada

In the United States, the dominant pressure unit is psi (pounds per square inch). However, in sectors with international links—like automotive manufacturing, oil & gas, and industrial equipment production—the bar unit is also used.

-

Automotive shops working on European or Asian vehicles frequently use bar unit readings for tire pressures and boost pressure gauges.

-

Multinational companies operating in both imperial and metric markets often provide dual markings (psi and bar) on their instrumentation to accommodate global standards.

In Canada, which uses both imperial and metric systems, the bar unit sees moderate use—especially in bilingual product documentation or in systems influenced by European engineering standards.

3. Legal Status and International Standards

Although not part of the SI, the bar unit is recognized by ISO (International Organization for Standardization), and DIN (Deutsches Institut für Normung) standards. It is legally accepted for use with SI units, which means it can appear on product labels, technical documentation, and engineering schematics.

Examples:

-

ISO 80000-4 includes pressure units and references the bar unit in explanatory notes.

-

Many DIN standards specify pressure in bar for pneumatic and hydraulic system design.

This international acceptance allows the bar unit to serve as a bridge between metric and non-metric systems, improving interoperability and reducing conversion errors.

4. Cultural and Practical Preference

The bar unit has become a default unit in many consumer products and user interfaces because of its readability and relatability. For example:

-

Tire inflators and air compressors often have a bar scale because the numbers (e.g., 2.0 bar) are easier to comprehend than 200,000 pascals.

-

Dive watches and computers use the bar unit to show depth-related pressure with minimal confusion.

-

Weather broadcasts, especially outside North America, use mbar, which is directly tied to the bar unit.

Online Bar Unit Converters and Software Tools

With the globalization of engineering and manufacturing processes, professionals often need to convert the bar unit into other pressure units like pascals, psi, atm, or torr. Fortunately, a variety of online tools and engineering software platforms are available to make these conversions quick, accurate, and user-friendly.

1. Online Bar Unit Converters

Online converters are especially useful for students, engineers, and technicians needing fast conversions without installing software. These tools typically offer real-time conversion between the bar unit and multiple other units of pressure.

Popular online bar unit converters include:

-

UnitConverters.net – A simple tool that allows conversion between bar, Pa, psi, atm, mmHg, and more.

-

RapidTables.com – Offers an intuitive interface for converting the bar unit into dozens of alternative units.

-

Google Search – Typing “3 bar to psi” directly into the search bar instantly provides results.

-

Omni Calculator – Features unit-specific tools and engineering calculators that integrate the bar unit seamlessly.

These tools support both desktop and mobile access, making them highly practical for on-site technicians and field engineers.

2. Engineering and Scientific Software Tools

In professional and academic environments, specialized software platforms often include bar unit compatibility as a built-in feature.

-

MATLAB: Engineers can input and convert pressure values using the bar unit in simulations and modeling.

-

AutoCAD Plant 3D: Supports piping and instrumentation design where bar unit inputs are common.

-

Aspen HYSYS / Aspen Plus: Widely used in process simulation, these tools allow pressure specification in bars for reactors, compressors, and columns.

-

EES (Engineering Equation Solver): Enables thermodynamic calculations with direct input/output in the bar unit.

These platforms often include conversion libraries, pressure unit toggles, and built-in functions for calculating pressure drops, flow rates, or heat transfer—all with the bar unit as a selectable option.

3. Mobile Apps for On-the-Go Conversions

Several free and paid apps are available on iOS and Android platforms that support bar unit conversions:

-

Convert Units

-

Engineering Unit Converter

-

Pressure Converter Pro

These apps allow offline conversion between bar unit, psi, atm, kPa, and more, making them invaluable for technicians in the field.

Whether you’re designing a pressure system, conducting lab experiments, or working on a vehicle, online converters and engineering tools simplify working with the bar unit. With a wide range of platforms supporting bar-to-psi, bar-to-kPa, and other conversions, professionals can save time and reduce errors—ensuring accuracy in both documentation and real-world applications.

Advantages and Limitations of the Bar Unit

The bar unit has become one of the most widely recognized pressure units in industrial and technical environments due to its practical advantages. However, like all non-SI units, it also comes with certain limitations, especially in formal scientific documentation. Understanding both sides helps determine when and where the bar unit is the most appropriate choice.

Advantages of the Bar Unit

✅ Intuitive and Readable

One of the biggest strengths of the bar unit is its alignment with real-world conditions. For example, atmospheric pressure at sea level is approximately 1.013 bar, which makes the bar unit extremely relatable and easy to interpret in meteorology, diving, and industrial contexts.

✅ Metric-Based Simplicity

Since 1 bar = 100,000 pascals, the bar unit fits cleanly into the metric system. It avoids the large and cumbersome numbers associated with the pascal while still maintaining compatibility with SI-based engineering calculations.

✅ Widely Used Across Industries

From automotive tire inflation to hydraulic systems and weather forecasting, the bar unit is consistently used across multiple industries. It also appears on many types of instruments, such as pressure gauges, transducers, and dive computers, providing standardized and clear pressure references.

✅ Supported by International Standards

While not an SI unit, the bar unit is legally accepted for use with the SI and is referenced in standards like ISO, DIN, and other international engineering guidelines.

Limitations of the Bar Unit

❌ Not an Official SI Unit

Despite its metric basis, the bar unit is not part of the official International System of Units. This can be problematic in academic or scientific publications that require strict adherence to SI conventions.

❌ Potential for Unit Confusion

Because different regions use different pressure units (e.g., psi in the U.S., kPa in Canada, and bar in Europe), there is a risk of misinterpretation if units are not clearly specified. Instruments labeled only in bar unit may cause issues in global operations if conversions are overlooked.

❌ Not Ideal for Very High or Low Pressures

In extremely high-pressure or vacuum environments, more appropriate units—such as kbar, Pa, or torr—may offer better precision or clarity than the standard bar unit.

Educational Importance and How to Teach the Bar Unit

Teaching the bar unit is a fundamental part of any curriculum that covers physics, engineering, meteorology, or industrial sciences. Because pressure is a core physical quantity encountered in real-world applications, introducing students to the bar unit builds essential knowledge that bridges classroom concepts and practical, hands-on experience.

1. Introducing the Concept of Pressure Using the Bar Unit

The bar unit provides a clear and intuitive way to introduce the concept of pressure. Instead of using pascals, which can be too abstract due to their small size (1 Pa = 1 N/m²), the bar unit offers relatable values that correspond to everyday experiences.

For example:

-

Atmospheric pressure ≈ 1.013 bar

-

Car tire pressure ≈ 2.2 bar

-

Scuba diving pressure increases by 1 bar every 10 meters of depth

By anchoring lessons around these familiar examples, educators can help students grasp what pressure is and how it behaves.

2. Using Laboratory Experiments and Demonstrations

In science and engineering labs, students can perform pressure-related experiments using sensors, gauges, or manometers calibrated in the bar unit. This exposure reinforces theoretical knowledge while building confidence in reading and interpreting real-world instruments.

Common lab activities include:

-

Boyle’s Law demonstrations with compressed gas

-

Tire inflation exercises in automotive classes

-

Water column pressure measurements (hydrostatics)

Displaying results in the bar unit makes data easier to visualize and relate to daily life.

3. Integrating the Bar Unit into Curriculum Materials

Textbooks and instructional content should highlight the bar alongside SI pressure units like pascals and kilopascals. Practice problems should encourage:

-

Conversions between bar and other units (psi, atm, Pa)

-

Real-life applications in problem-solving

-

Interpretation of data sheets or weather reports using the bar

Digital tools like unit converters, simulation software, and mobile apps can also support student learning.

Future of the Bar Unit in a Standardizing World

As global industries increasingly adopt and enforce SI (International System of Units) standards, the future of non-SI units like the bar has become a topic of ongoing discussion. Despite not being an SI unit, the bar continues to hold strong in many sectors due to its practicality, ease of use, and deep-rooted presence in technical systems and everyday operations.

1. SI Standardization Trends

International bodies such as the Bureau International des Poids et Mesures (BIPM) actively promote exclusive use of SI units, including the pascal (Pa) for pressure. In theory, widespread SI adoption would gradually phase out non-SI alternatives like the bar unit.

However, real-world adoption is often more complex. The bar unit, which equals exactly 100,000 pascals, is still preferred in many industries where numerical simplicity and usability outweigh strict SI compliance. For instance, stating a tire pressure of 2.2 bar is more straightforward than saying 220,000 Pa.

2. Continued Industrial Dependence on the Bar Unit

Many critical industries—including automotive, oil & gas, and HVAC—have integrated the bar unit deeply into their instrumentation, documentation, and training systems. As long as these industries maintain legacy equipment and global operations that favor the bar unit, widespread replacement with SI alternatives is unlikely.

Additionally, the bar unit is supported in many international standards (e.g., ISO, DIN, IEC) and engineering tools, which further solidifies its ongoing use despite non-SI status.

3. Bridging Between Systems

The future may not require abandoning the bar but rather embracing tools and practices that facilitate seamless unit conversion. Many digital systems, engineering software platforms, and IoT devices already allow users to input and view pressure in bar, even if backend calculations default to pascals.

Such hybrid approaches can support global collaboration while gradually easing newer generations into full SI adoption—without disrupting current workflows.

Frequently Asked Questions (FAQ) About the Bar Unit

Understanding the bar unit and its applications can raise questions for students, engineers, and everyday users. Below are some of the most frequently asked questions to clarify how the bar unit is used, converted, and interpreted.

1. Is the bar part of the SI system?

No, the bar unit is not officially part of the SI system, even though it is derived from metric principles. The SI unit for pressure is the pascal (Pa). However, the bar unit is legally accepted for use with SI units and widely used in many industries due to its practicality.

2. What is 1 bar equal to in pascals?

One bar is exactly 100,000 pascals (Pa). This is a defined value and serves as the basis for many conversion calculations in physics and engineering.

3. How does the bar compare to atmospheric pressure?

Atmospheric pressure at sea level is approximately 1.01325 bar, making the bar very close to 1 atmosphere (atm). This proximity is one reason why the bar is so intuitive and widely used for everyday pressure measurement.

4. What is the difference between bar and psi?

-

1 bar is approximately 14.5038 psi (pounds per square inch).

-

Psi is used mainly in the United States and countries using imperial units, while the bar unit is more common in Europe and metric-based regions.

Understanding the relationship between these units is important in industries like automotive and aerospace, which often involve cross-border collaboration.

5. Can I use the bar unit in scientific reports or publications?

While the bar unit is commonly used in technical and engineering fields, scientific journals and institutions typically prefer SI units, such as pascals (Pa). For formal scientific work, pressure values expressed in bar units should be converted to pascals.

6. Why is the bar unit so popular despite not being SI?

The bar unit is popular because:

-

It simplifies large numbers (e.g., 100,000 Pa = 1 bar)

-

It aligns closely with atmospheric pressure

-

It is familiar to engineers, mechanics, and technicians

-

Many pressure instruments, such as gauges and sensors, are calibrated in bar units

Its practical usability often outweighs its non-SI status in many industrial settings.

7. What’s the difference between bar, mbar, and kbar?

-

mbar (millibar) = 0.001 bar → Used in meteorology

-

bar = 1 bar → Common in industry and engineering

-

kbar (kilobar) = 1,000 bar → Used in high-pressure science and geophysics

Each version of the bar unit is scaled to match specific pressure measurement needs.

8. Where is the bar most commonly used?

The bar is widely used in:

-

Automotive (tire and fuel pressure)

-

Oil & gas industry

-

Diving equipment

-

Weather reporting (as mbar)

-

Industrial pressure systems (hydraulics, compressors, etc.)

Its versatility and simplicity make it a preferred pressure unit in both consumer and professional tools.

Conclusion

The bar unit remains one of the most practical and widely recognized non-SI pressure units in modern industry and daily applications. Defined as exactly 100,000 pascals, the bar offers a convenient scale for measuring pressure in systems ranging from car tires and scuba tanks to high-pressure hydraulic circuits and atmospheric monitoring instruments.

Despite its status as a non-SI unit, the bar unit continues to be legally accepted and widely applied in engineering design, instrumentation, manufacturing, weather forecasting, and more. Its intuitive scale—close to atmospheric pressure—makes it easy to teach, easy to understand, and easy to apply in real-world situations.

Throughout this article, we’ve explored the historical background, mathematical conversions, industrial applications, educational relevance, global usage trends, and digital tools supporting the bar . We’ve also addressed common questions that engineers, students, and technicians encounter when working with this unit.

As the world continues to adopt standardized measurement systems, the bar is likely to maintain its role as a user-friendly bridge between theoretical precision and industrial practicality. Its ongoing relevance ensures that professionals across sectors will continue to rely on the bar to measure and communicate pressure accurately and effectively.