In the world of physics and engineering, the concept of force is fundamental to understanding how objects interact and move. Force is the influence that causes an object to undergo a change in motion, direction, or shape. To quantify and communicate these influences clearly, scientists and engineers rely on a unit of force—a standardized measure that expresses the magnitude of force applied.

The unit of force is essential not only in scientific research but also in everyday applications. Whether calculating the force needed to lift a heavy object, designing a bridge that can withstand strong winds, or measuring the thrust of a rocket engine, having a clear and consistent unit of force allows accurate measurement, analysis, and communication.

This article will explore the concept of the unit of force in depth. We will begin by understanding what force is and why it requires a specific unit of measurement. Then, we will examine the most widely used units of force around the world, including the internationally recognized Newton. Additionally, the article will cover how to convert between different units of force, the tools used to measure force, and practical applications across various fields.

By the end of this article, readers will have a comprehensive understanding of the unit of force, its importance, and how it shapes our ability to quantify and harness physical interactions in science and everyday life.

1. What is SI Unit of Force ?

The SI unit of force is the Newton (N).

Explanation:

-

One Newton is defined as the force required to accelerate a mass of 1 kilogram by 1 meter per second squared.

-

In formula form:

1 N=1 kg×1 m/s2 -

The Newton is a derived unit in the International System of Units (SI), based on the fundamental units of mass (kilogram), length (meter), and time (second).

This makes the Newton a coherent and universal unit for measuring force in science and engineering worldwide.

2. The Concept of Force

Force is a fundamental concept in physics that describes an interaction capable of changing an object’s motion or shape. Simply put, force can make something start moving, stop moving, speed up, slow down, or change direction. Because force causes these changes, understanding it is crucial in fields like mechanics, engineering, and even biology.

According to Sir Isaac Newton’s laws of motion, force plays a central role in how objects behave. Newton’s Second Law, often written as F = ma (force equals mass times acceleration), directly relates force to the motion of objects. This law shows that to accelerate an object, a force must be applied, and the amount of force depends on the object’s mass and the desired acceleration.

Force is also a vector quantity, meaning it has both magnitude (size) and direction. For example, pushing a box to the right with a certain strength is different from pushing it to the left with the same strength because the direction matters.

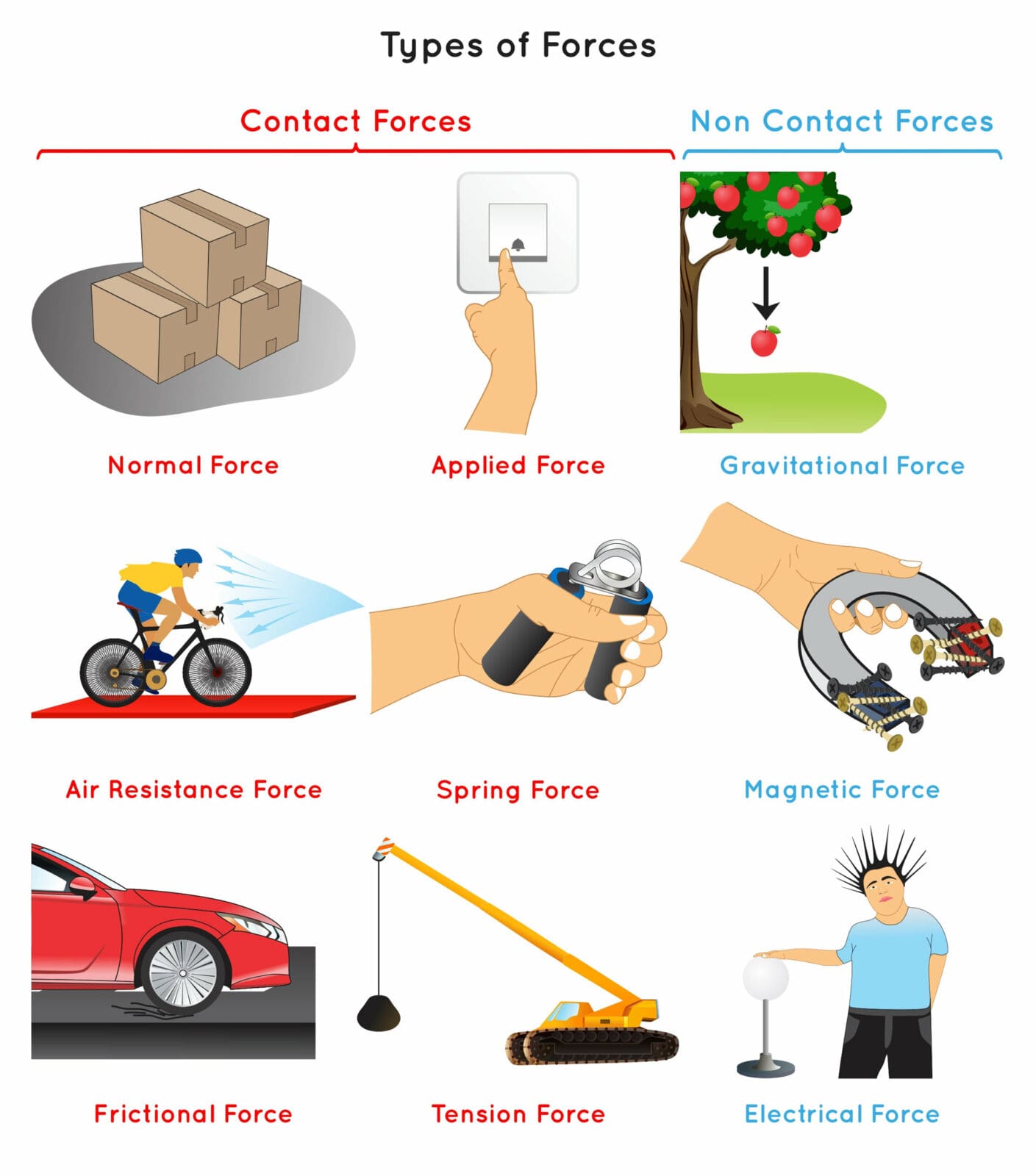

There are many types of forces in the physical world, such as:

-

Gravitational force: The force that pulls objects toward the Earth or other masses.

-

Frictional force: The resistance force that acts opposite to the motion when two surfaces slide against each other.

-

Tension force: The force transmitted through a string, rope, or cable when it is pulled tight.

-

Normal force: The support force exerted by a surface perpendicular to the object resting on it.

-

Electromagnetic force: Forces between charged particles.

Because force can be exerted in many ways and affects various systems, having a clear and consistent unit of force is necessary to quantify and compare these effects accurately. This need leads us to explore the different units used to measure force, starting with the most common—the Newton.

3. Historical Development of Units of Force

The measurement of force has evolved significantly over time, reflecting humanity’s growing understanding of physics and the need for standardization in science and engineering. Before the establishment of formal units, force was often described qualitatively, such as “strong” or “weak,” which made precise communication and calculation difficult.

In early history, people used local or customary measures based on familiar references—for example, the force needed to lift a known weight or the pressure exerted by water in a certain container. These informal methods were practical but lacked consistency across regions and applications.

The scientific revolution, particularly through the work of Sir Isaac Newton in the 17th century, laid the groundwork for defining force in quantitative terms. Newton’s formulation of the laws of motion introduced the idea that force could be measured as a product of mass and acceleration, a breakthrough that allowed forces to be expressed numerically.

However, the question remained: in what units should force be measured?

During the 18th and 19th centuries, various measurement systems developed in different countries, such as the British Imperial system and the French metric system. The lack of a universal standard unit of force caused confusion and errors, especially in international trade and scientific research.

This challenge was addressed by the creation of the International System of Units (SI) in the mid-20th century, which established the Newton (N) as the official unit of force. The Newton is defined based on fundamental units of mass (kilogram), length (meter), and time (second), making it a coherent and universally accepted standard.

Before the Newton became widely adopted, other units like the pound-force and kilogram-force were commonly used, especially in the British Imperial and metric gravitational systems, respectively. These units are still in use in some industries and regions but are gradually being replaced by the Newton in scientific and engineering contexts worldwide.

Understanding this historical development helps explain why multiple units of force exist today and why the Newton holds a central place in the measurement of force.

4. The SI Unit of Force: The Newton (N)

The Newton (N) is the internationally recognized unit of force in the International System of Units (SI). Named after Sir Isaac Newton in honor of his groundbreaking work in physics, the Newton provides a precise and standardized way to measure force.

Definition of the Newton

One Newton is defined as the amount of force required to accelerate a one-kilogram mass by one meter per second squared. In formula terms:

1 Newton (N) = 1 kilogram × meter per second squared (kg·m/s²)

This definition directly relates the unit of force to the basic SI units of mass (kilogram), length (meter), and time (second), making the Newton a derived unit.

Practical Examples of the Newton

To better understand the magnitude of one Newton, consider these examples:

-

The force needed to hold an apple at rest in your hand is roughly 1 Newton.

-

When you push a light object such as a small book across a table, the applied force is typically a few Newtons.

Advantages of Using the Newton

The Newton’s use as the standard unit of force offers several benefits:

-

Universality: Since it is based on SI base units, the Newton is recognized and used worldwide, facilitating international scientific collaboration and engineering work.

-

Coherence: The Newton fits seamlessly into the SI system, allowing easy conversion and calculation without extra factors.

-

Precision: Being based on measurable fundamental quantities, the Newton allows highly accurate force measurements.

Symbol and Usage

The symbol for the Newton is N. In scientific and technical writing, it is important to use the symbol correctly and consistently to avoid confusion with other units or variables.

In summary, the Newton is the cornerstone unit of force in modern science and engineering. Its clear definition and universal acceptance have made it indispensable for accurately describing and quantifying forces in diverse applications, from physics labs to industrial machinery.

5. Other Units of Force Around the World

While the Newton (N) is the official unit of force in the International System of Units (SI), several other units are still used globally, especially in regions or industries where traditional measurement systems prevail. Understanding these units is important for conversions, historical context, and applications in specific fields.

Pound-Force (lbf)

The pound-force (lbf) is commonly used in the United States and countries that use the Imperial or US customary systems. It is defined as the force exerted by gravity on a mass of one pound at the Earth’s surface. Formally:

-

1 pound-force ≈ 4.44822 Newtons

Pound-force is widely used in engineering, especially in mechanical and civil applications such as structural design and automotive industries.

Kilogram-Force (kgf or kp)

The kilogram-force is another non-SI unit of force, defined as the force exerted by gravity on one kilogram of mass. It is often used in some parts of Europe and Asia, especially in older engineering contexts.

-

1 kilogram-force = 9.80665 Newtons

Though less precise than the Newton, the kilogram-force provides an intuitive sense of force based on everyday mass under Earth’s gravity.

Dyne

The dyne is a smaller unit of force used mainly in the centimeter-gram-second (CGS) system, which is less common today but still used in certain physics fields.

-

1 dyne = 10⁻⁵ Newtons

The dyne is useful for measuring very small forces, such as those encountered in molecular or surface physics.

Other Units

There are also less common or specialized units of force, including:

-

Ounce-force (ozf): Used in small force measurements, especially in manufacturing or packaging.

-

Ton-force: Used in heavy industry, often relating to the force equivalent to one ton under gravity.

Comparing Units of Force

| Unit | Symbol | Approximate Value in Newtons |

|---|---|---|

| Newton | N | 1 N |

| Pound-force | lbf | 4.44822 N |

| Kilogram-force | kgf or kp | 9.80665 N |

| Dyne | dyn | 0.00001 N (1 × 10⁻⁵ N) |

| Ounce-force | ozf | 0.27801 N |

Knowing these units and their relationships is critical when interpreting force measurements from different sources or working in international environments.

6. Conversion Between Units of Force

Because different parts of the world and various industries use multiple units of force, converting between these units is a necessary skill for engineers, scientists, and technicians. Accurate conversions ensure consistency and prevent errors in calculations, design, and communication.

Why Convert Units of Force?

Converting units of force is essential because:

-

Different countries or industries may use different units (e.g., Newtons vs. pound-force).

-

Technical documents, machinery specifications, or scientific data may reference force in varying units.

-

International collaboration and trade require common understanding.

Common Conversion Formulas

Here are the key conversion factors between the most frequently used units of force:

-

1 Newton (N) = 0.224809 pound-force (lbf)

-

1 pound-force (lbf) = 4.44822 Newtons (N)

-

1 Newton (N) = 0.101972 kilogram-force (kgf)

-

1 kilogram-force (kgf) = 9.80665 Newtons (N)

-

1 dyne (dyn) = 1 × 10⁻⁵ Newtons (N)

-

1 Newton (N) = 10⁵ dynes (dyn)

Examples of Unit Conversion

Example 1: Convert 50 Newtons to pound-force.

Using the formula:

50 N × 0.224809 lbf/N = 11.24 lbf

Example 2: Convert 100 pound-force to Newtons.

Using the formula:

100 lbf × 4.44822 N/lbf = 444.82 N

Conversion Tables

For ease of use, many engineers refer to conversion tables listing common force values in multiple units. These tables help quickly translate measurements without recalculating.

| Force (N) | Force (lbf) | Force (kgf) | Force (dyn) |

|---|---|---|---|

| 1 | 0.2248 | 0.10197 | 100,000 |

| 10 | 2.248 | 1.0197 | 1,000,000 |

| 100 | 22.48 | 10.197 | 10,000,000 |

| 1000 | 224.8 | 101.97 | 100,000,000 |

Tools for Conversion

Modern calculators, engineering software, and online converters simplify the process of converting between units of force. However, understanding the underlying conversions helps verify results and prevent errors.

7. Measuring Force: Instruments and Techniques

Accurate measurement of force is essential in scientific experiments, engineering design, quality control, and many practical applications. To quantify force reliably, various instruments and techniques have been developed, each suited to different types of force and levels of precision.

Common Instruments to Measure Force

1. Spring Scales

Spring scales are one of the simplest tools to measure force, based on Hooke’s Law, which states that the force applied to a spring is proportional to its extension or compression. The scale shows force values by the displacement of a spring inside the device.

-

Used for small to moderate forces

-

Portable and easy to use

-

Limited accuracy compared to modern devices

2. Dynamometers

Dynamometers are instruments designed to measure force, torque, or power. Mechanical dynamometers use springs or levers, while electronic versions use sensors such as strain gauges.

-

Used in automotive testing, machinery, and biomechanics

-

Available in a range of sizes for different force levels

3. Load Cells

Load cells are highly accurate electronic sensors that convert force into an electrical signal. They commonly use strain gauges, which change resistance when stretched or compressed.

-

Widely used in industrial weighing, testing machines, and robotics

-

Can measure very small to very large forces

-

Require calibration and proper setup

Techniques for Force Measurement

-

Static Force Measurement: Measuring force applied slowly or held constant, such as weighing an object or testing material strength.

-

Dynamic Force Measurement: Measuring forces that change rapidly over time, such as impact forces or vibrations, requiring fast response sensors.

-

Indirect Force Measurement: Sometimes force is calculated indirectly through other measured quantities, such as pressure or acceleration, using known relationships.

Calibration and Accuracy

Proper calibration of force measuring instruments is crucial for accuracy. Calibration involves comparing the instrument’s readings to known standard forces, often provided by calibration weights or reference devices.

Factors affecting measurement accuracy include:

-

Environmental conditions (temperature, humidity)

-

Instrument wear and tear

-

Proper mounting and alignment

Modern Advances in Force Measurement

Advances in sensor technology, such as piezoelectric sensors and fiber optic force sensors, allow more precise, reliable, and miniaturized force measurements. These are especially useful in micro- and nano-scale applications like medical devices and materials research.

8. Applications of Units of Force

The unit of force plays a critical role across many fields, from everyday tasks to advanced engineering and scientific research. Understanding and using the correct unit of force enables precise design, analysis, and communication of forces involved in numerous applications.

Engineering and Construction

In engineering, accurate measurement and application of force are essential to ensure structural safety and functionality. Forces like tension, compression, shear, and torsion are calculated and expressed using standard units of force to design bridges, buildings, machinery, and vehicles. For example, engineers calculate the force that beams must withstand to prevent collapse and use Newtons or pound-force depending on the system.

Automotive and Aerospace Industries

In the automotive sector, forces are critical when designing engines, suspensions, and brakes. The force exerted by engines or the braking force applied to stop a vehicle is measured in Newtons or pound-force. Similarly, aerospace engineers rely on units of force to calculate thrust, lift, and drag forces on aircraft and spacecraft, which directly influence performance and safety.

Medical Field

Biomechanics studies the forces exerted by muscles and on bones during movement. Units of force help quantify these internal and external forces, assisting in prosthetic design, rehabilitation, and ergonomic assessments. Devices like force plates and dynamometers measure forces in Newtons to analyze gait or grip strength.

Everyday Applications

Even in daily life, understanding force helps explain how objects move and interact. Whether pushing a shopping cart, opening a door, or lifting groceries, the force applied can be described and measured using a unit of force. This knowledge is useful for product design, safety assessments, and improving convenience.

Manufacturing and Quality Control

In manufacturing, forces applied during machining, pressing, or assembly must be controlled and measured precisely. Units of force guide machine calibration and ensure products meet quality standards. For example, the force needed to press-fit components or tighten bolts is specified in Newtons or pound-force.

Research and Development

Scientists use units of force in experiments to explore physical phenomena, material properties, and new technologies. Precise force measurements allow testing of tensile strength, elasticity, and friction coefficients, c

9. Challenges and Misconceptions About Units of Force

Although the concept of a unit of force is straightforward in theory, in practice, many challenges and common misconceptions can lead to confusion or errors in measurements and calculations.

Confusing Force Units with Mass Units

One of the most frequent misconceptions is confusing units of force with units of mass. For example, kilograms (kg) measure mass, while Newtons (N) measure force. The kilogram-force (kgf) unit further complicates this because it represents the force exerted by gravity on a kilogram of mass. People sometimes mistakenly treat kilograms as force, especially in everyday contexts, which can cause inaccuracies in scientific or engineering work.

Mixing Different Unit Systems

The coexistence of multiple unit systems, such as SI (Newtons) and Imperial (pound-force), often causes errors during conversions or communication. Engineers and scientists must be vigilant when interpreting force values, ensuring units are correctly identified and converted.

Incorrect Application of Conversion Factors

Applying the wrong conversion factors or forgetting to convert units can lead to significant calculation mistakes. For example, using mass values directly as force without multiplying by gravitational acceleration (9.80665 m/s²) results in incorrect force estimates.

Overlooking Direction in Force Calculations

Since force is a vector quantity, neglecting its direction during addition or subtraction can produce wrong results. Misunderstanding the vector nature of force often leads to conceptual and practical errors.

Calibration and Measurement Errors

Instruments measuring force require regular calibration. Using uncalibrated or improperly maintained devices can produce inaccurate readings, impacting experiments or product quality.

Dimensional Analysis Neglect

Failing to check units and dimensions during calculations can cause inconsistencies and mistakes. Proper dimensional analysis helps verify that the units of force and related quantities are correctly handled.

10. Future Trends in Force Measurement

The field of force measurement is undergoing significant transformation, driven by advancements in sensor technology, data analytics, and automation. As industries strive for greater precision, efficiency, and integration, several key trends are emerging in force measurement.

1. Miniaturization and Integration

The demand for smaller, more compact force sensors is increasing, particularly in applications where space is limited. Innovations are leading to the development of miniature sensors that maintain high accuracy while occupying minimal space.

2. Wireless and Remote Monitoring

Wireless force sensors are becoming more prevalent, allowing for remote monitoring and data collection without the need for physical connections. This trend is particularly beneficial in applications where traditional wired sensors are impractical, such as in rotating machinery or hazardous environments.

3. Smart Sensors and IoT Integration

The integration of force sensors with the Internet of Things (IoT) enables real-time data analysis and predictive maintenance. Smart sensors equipped with onboard processing capabilities can analyze data locally, reducing the need for constant communication with central systems and enhancing response times.

4. Advanced Materials and Sensing Technologies

Researchers are exploring the use of advanced materials, such as quantum tunneling composites and piezoelectric materials, to enhance the sensitivity and performance of force sensors. These materials can offer improved accuracy and responsiveness in various applications.

5. High-Precision and Multi-Axis Measurement

There is a growing need for force sensors capable of measuring forces in multiple directions simultaneously. Multi-axis force sensors are being developed to provide comprehensive data on the forces acting on an object, which is crucial in applications like robotics and aerospace engineering.

6. Environmental Adaptability

Future force sensors are being designed to withstand extreme environmental conditions, including high temperatures, corrosive substances, and high-pressure environments. This adaptability is essential for applications in industries such as oil and gas, aerospace, and deep-sea exploration.

7. Data Analytics and Machine Learning

The incorporation of machine learning algorithms into force measurement systems allows for advanced data analysis, anomaly detection, and optimization of processes. By analyzing large datasets, these systems can provide insights that lead to improved performance and reduced downtime.

11. Summary and Conclusion

Understanding the unit of force is fundamental to grasping how physical interactions shape the world around us. From the basic definition of force as a cause of motion or deformation to the adoption of the Newton as the standard unit of force, this measurement enables scientists, engineers, and everyday users to quantify and communicate forces accurately and consistently.

Throughout this article, we have explored the concept of force, the historical evolution of units of force, and the variety of units used worldwide, such as the pound-force and kilogram-force. We discussed how to convert between these units, the instruments used to measure force, and numerous practical applications across engineering, medicine, manufacturing, and daily life.

Additionally, we highlighted common challenges and misconceptions involving units of force, emphasizing the importance of clarity and proper usage. Looking ahead, emerging technologies and innovations promise to refine force measurement further, enabling higher precision, integration with smart systems, and adaptability to diverse environments.

By mastering the principles and applications of the unit of force, individuals and professionals can enhance their understanding of physical phenomena and improve the safety, efficiency, and innovation in many fields. The unit of force remains a cornerstone of science and technology, vital for interpreting and harnessing the forces that govern our universe.