Pressure measurement is essential across numerous engineering, scientific, and industrial applications, where accuracy, clarity, and consistency are crucial. Among the various units of pressure measurement, MPa Units stand out as one of the most widely utilized due to their practicality and precision. MPa, or Megapascal, belongs to the International System of Units (SI), representing pressure or stress equivalent to one million pascals. The wide adoption of MPa Units across multiple sectors, including civil engineering, mechanical engineering, automotive, aerospace, and materials testing, highlights their fundamental role in modern industry and technology.

Historically, MPa Units were established to standardize pressure measurement internationally, providing engineers and scientists a clear and uniform reference. Prior to the adoption of MPa Units, inconsistencies arising from diverse local measurement systems posed significant challenges to communication and accuracy. By unifying these measurements under the umbrella of MPa Units, industries and global engineering practices have achieved streamlined communication, enhanced safety, and improved reliability in numerous applications.

Understanding MPa Units thoroughly is pivotal for professionals involved in design, testing, and operations across diverse fields. Misinterpretation or misuse of MPa Units can lead to critical errors affecting the integrity and safety of structures and mechanical systems. Therefore, mastering MPa Units and their correct application becomes imperative not just for technical accuracy but also for maintaining high standards in industry safety, efficiency, and compliance.

This article will provide a comprehensive examination of MPa Units, covering their definition, practical applications, conversion methods to other units, measurement techniques, relevant industry standards, common mistakes, and future trends. By the end of this discussion, readers will gain a thorough grasp of MPa Units, equipped to accurately implement and interpret these vital measurements in their professional activities.

What Are MPa Units?

MPa Units, short for Megapascals, are a standard unit of pressure and stress measurement in the metric system. One MPa equals 1,000,000 pascals (Pa), or 1 newton per square millimeter (N/mm²). MPa Units are widely used across engineering disciplines, especially in materials testing, structural analysis, hydraulic systems, and manufacturing processes where large pressures or forces are involved.

Understanding the Basics:

-

1 MPa = 1,000,000 Pa

-

1 MPa = 145.038 psi (pounds per square inch)

-

1 MPa = 10 bar

-

1 MPa = 10.197 kg/cm²

Unlike smaller units like pascals or kilopascals, MPa Units are ideal for expressing high-pressure values concisely and clearly. For example, the compressive strength of concrete or the tensile strength of steel is commonly expressed in MPa, such as “concrete with a compressive strength of 30 MPa.”

Why MPa Units Matter

Using MPa Units allows engineers and technicians to:

-

Accurately calculate and compare material strength

-

Safely design hydraulic and pneumatic systems

-

Standardize test results across industries and regions

-

Comply with international engineering standards (e.g., ISO, ASTM, ASME)

In essence, MPa Units are a critical part of the language of engineering—precise, universal, and trusted worldwide.

Understanding MPa Units

To fully appreciate the significance of MPa Units, it is essential to first understand what they represent and how they are used. MPa Units, or Megapascals, are a metric measurement of pressure and stress. One MPa equals 1,000,000 pascals (Pa). The pascal (Pa), the SI unit for pressure, is defined as one newton per square meter (N/m²). Therefore, MPa Units are particularly suitable for describing higher levels of pressure or stress, where smaller units like Pa or kPa would result in very large, unwieldy numbers.

What Does 1 MPa Mean?

When we say 1 MPa, we are referring to a pressure of one million newtons per square meter. This magnitude is common in engineering contexts—for example, the compressive strength of concrete is often measured in MPa Units, typically ranging between 20 MPa and 40 MPa in standard constructions.

Derivation and Mathematical Background

MPa is derived from the base SI unit of pressure:

-

1 Pa = 1 N/m²

-

1 MPa = 1,000,000 Pa = 1,000,000 N/m²

This derivation links pressure (MPa Units) with force and area, indicating that any application of MPa Units always involves a force distributed over a specific surface area.

Why Use MPa Units?

The primary reason for using MPa Units is efficiency and clarity in communication. While other pressure units like psi (pounds per square inch) or bar are still in use, especially in non-metric countries, MPa Units offer a universal standard. Their usage simplifies technical documentation, analysis, and cross-border engineering collaborations. Additionally, MPa Units help avoid excessive use of zeroes and decimals, especially when dealing with high pressures, which improves readability and reduces the risk of errors.

Comparison with Other Pressure Units

Understanding the relationship between MPa Units and other pressure measurements can help professionals interpret data more accurately:

-

1 MPa = 10 bar

-

1 MPa = 145.038 psi

-

1 MPa = 10.197 kg/cm²

These conversion factors allow engineers and technicians to switch between different units depending on regional preferences or application-specific requirements while still relying on MPa Units as a fundamental reference point.

Common Applications of MPa Units

MPa Units are extensively used in the following fields:

-

Civil Engineering: Measuring concrete and soil strength.

-

Mechanical Engineering: Determining stress and tensile strength of metals.

-

Automotive Industry: Monitoring engine pressure and tire inflation.

-

Hydraulic Systems: Setting operating pressures for safe system performance.

-

Aerospace: Evaluating material durability under extreme pressure conditions.

In all these fields, MPa Units provide a reliable and internationally recognized standard that supports safety, performance, and regulatory compliance.

Converting MPa Units to Other Pressure Units

Understanding how to convert MPa Units into other commonly used pressure units is critical in global engineering and scientific disciplines. While MPa Units are widely used, especially in SI (metric) systems, many regions or industries still rely on other units such as psi, bar, and kg/cm². Accurate conversion ensures consistency in calculations, design specifications, and safety evaluations.

- Megapascal To Torr

- Megapascal To Kilogram-force/square Meter

- Megapascal To Kilogram-force/sq. Cm

- Megapascal To Kilogram-force/sq. Millimeter

- Megapascal To Gram-force/sq. Centimeter

- Megapascal To Ton-force (Short)/sq. Foot

- Megapascal To Ton-force (Short)/sq. Inch

- Megapascal To Ton-force (Long)/square Foot

- Megapascal To Ton-force (Long)/square Inch

- Megapascal To Kip-force/square Inch

- Megapascal To Pound-force/square Foot

- Megapascal To Pound-force/square Inch

- Megapascal To Poundal/square Foot

- Megapascal To Dyne/square Centimeter

- Megapascal To Centimeter Mercury (0°c)

- Megapascal To Millimeter Mercury (0°c)

- Megapascal To Inch Mercury (32°f)

- Megapascal To Inch Mercury (60°f)

- Megapascal To Centimeter Water (4°c)

- Megapascal To Millimeter Water (4°c)

- Megapascal To Inch Water (4°c)

- Megapascal To Foot Water (4°c)

- Megapascal To Inch Water (60°f)

- Megapascal To Foot Water (60°f)

- Megapascal To Atmosphere Technical

- Megapascal To Millipascal

- Megapascal To Bar

- MPa To Psi

- Megapascal To Ksi

- Megapascal To Standard Atmosphere

- Megapascal To Exapascal

- Megapascal To Petapascal

- Megapascal To Terapascal

- Megapascal To Gigapascal

- Megapascal To Hectopascal

- Megapascal To Dekapascal

- Megapascal To Decipascal

- Megapascal To Centipascal

- Megapascal To Kilopascal

- Megapascal To Micropascal

- Megapascal To Nanopascal

- Megapascal To Picopascal

- Megapascal To Femtopascal

- Megapascal To Attopascal

- Megapascal To Newton/square Meter

- Megapascal To Newton/square Centimeter

- Megapascal To Newton/square Millimeter

- Megapascal To Kilonewton/square Meter

- Megapascal To Millibar

- Megapascal To Microbar

Why Conversion of MPa Units Matters

Engineering projects frequently involve multinational teams or equipment from different countries. One manufacturer may label system pressure in MPa Units, while another uses psi or bar. Improper conversions can lead to design errors, mechanical failure, or safety risks. Therefore, being proficient in converting MPa Units to other formats is essential.

Conversion Factors for MPa Units

Below are the most commonly used conversion factors for MPa Units:

-

1 MPa = 1,000,000 Pa (Pascals)

-

1 MPa = 10 bar

-

1 MPa = 145.038 psi (pounds per square inch)

-

1 MPa = 10.197 kg/cm²

-

1 MPa = 9.869 atm (standard atmospheres)

These conversion constants allow for rapid and accurate conversions across various units used in pressure-related calculations.

MPa Units to psi (Pounds per Square Inch)

The psi is widely used in North America. The conversion from MPa Units to psi is:

1 MPa = 145.038 psi

Example:

If a hydraulic system operates at 2.5 MPa, then:

2.5 MPa × 145.038 psi = 362.595 psi

MPa Units to Bar

The bar is a metric unit still popular in industries like meteorology and automotive pressure readings.

1 MPa = 10 bar

Example:

For a pressure of 3 MPa:

3 MPa × 10 = 30 bar

MPa Units to kg/cm²

The kilogram-force per square centimeter is often used in Asia and in older equipment specifications.

1 MPa = 10.197 kg/cm²

Example:

5 MPa × 10.197 = 50.985 kg/cm²

MPa Units to Pascals (Pa)

While the pascal is the SI base unit for pressure, it is typically too small for many practical engineering applications.

1 MPa = 1,000,000 Pa

Thus, converting from MPa Units simply involves multiplying by 1,000,000.

MPa Units to Atmospheres (atm)

The atmosphere is a unit based on average sea-level atmospheric pressure.

1 MPa ≈ 9.869 atm

Example:

1.2 MPa × 9.869 = 11.842 atm

Conversion Table for Quick Reference

| MPa Units | psi | bar | kg/cm² | atm |

|---|---|---|---|---|

| 0.1 MPa | 14.5038 | 1 | 1.0197 | 0.9869 |

| 0.5 MPa | 72.519 | 5 | 5.0985 | 4.9345 |

| 1 MPa | 145.038 | 10 | 10.197 | 9.869 |

| 2 MPa | 290.075 | 20 | 20.394 | 19.738 |

| 5 MPa | 725.189 | 50 | 50.985 | 49.345 |

Tools for Converting MPa Units

There are several reliable tools for converting MPa Units:

-

Online calculators: Quick web tools for inputting MPa and receiving multiple conversions instantly.

-

Engineering software: Programs like MATLAB, AutoCAD, and Excel support formulas for real-time conversion.

-

Mobile apps: Available on iOS and Android, these apps can convert MPa Units to any desired unit on the go.

Final Thoughts on Conversion

Precision in converting MPa Units is more than a mathematical task—it’s a professional necessity. Engineers, technicians, and analysts must ensure that pressure data is consistent and accurately translated across various units to support performance and safety in critical systems.

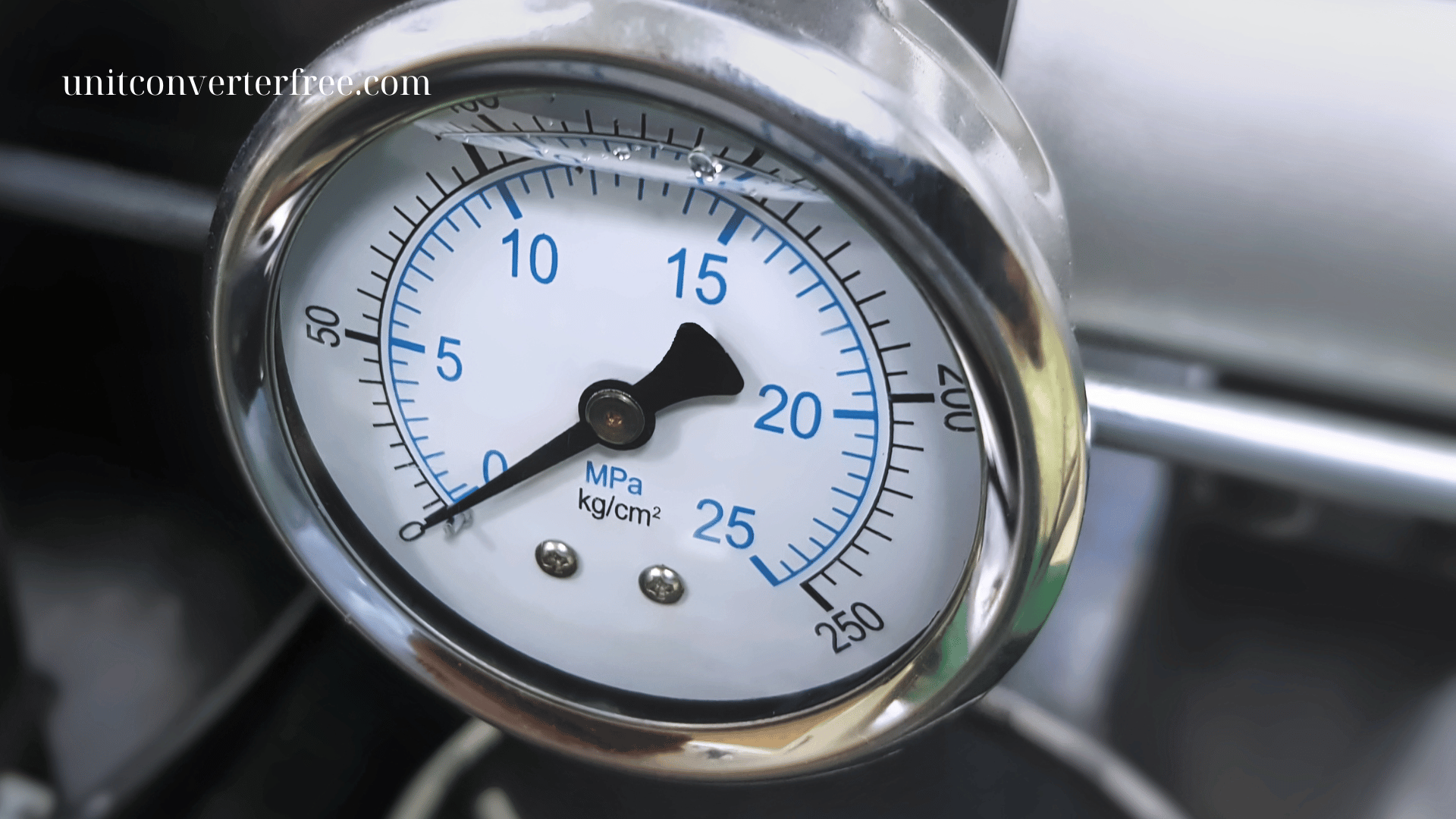

Measuring Instruments for MPa Units

Accurate measurement of pressure is critical across a wide range of industrial and scientific applications. To measure MPa Units precisely, specialized instruments are used that can withstand high pressures and deliver consistent readings. The selection of the correct measuring instrument not only ensures reliable data but also enhances safety, compliance, and operational efficiency.

Importance of Accurate MPa Units Measurement

Since MPa Units are used to quantify high pressures—often in mechanical systems, structural tests, or fluid dynamics—precision in measurement is vital. Errors in reading MPa Units can lead to incorrect design parameters, structural failures, or inefficient performance. Therefore, using the appropriate instruments for measuring MPa Units is essential for engineers and technicians.

Common Instruments Used to Measure MPa Units

Below are the most widely used instruments for measuring MPa Units:

1. Pressure Gauges (Analog and Digital)

-

Bourdon Tube Gauges: Often used in mechanical systems, they convert pressure into mechanical movement.

-

Digital Pressure Gauges: Display pressure readings in MPa Units and offer high accuracy, memory functions, and data logging.

-

Applications: Hydraulic systems, compressors, pumps.

Example: A digital gauge reading 2.8 MPa indicates a high-pressure condition in a hydraulic press.

2. Pressure Transducers and Sensors

-

Convert physical pressure into an electrical signal.

-

Common in industrial automation and control systems.

-

Available in various configurations that support output in MPa Units.

-

Ideal for remote monitoring and integration with PLCs (Programmable Logic Controllers).

Example: A pressure transducer sends a 4–20 mA signal corresponding to 0–10 MPa pressure in a fluid transport system.

3. Manometers

-

U-tube and inclined manometers can be used for low-pressure systems.

-

Not typically used for MPa ranges due to limited capacity but may be used in calibration scenarios or small-scale setups.

4. Hydraulic and Pneumatic Test Benches

-

Used in laboratory and quality control environments.

-

Allow for controlled pressurization and real-time monitoring of MPa values.

-

Often equipped with digital displays that read directly in MPa Units.

5. Data Loggers and Wireless Pressure Monitoring Devices

-

These tools are increasingly used in IoT-enabled environments.

-

Capable of storing pressure data in MPa Units over time.

-

Useful in predictive maintenance, system diagnostics, and environmental monitoring.

Best Practices for Measuring MPa Units

-

Calibration: Instruments measuring MPa Units should be regularly calibrated using certified standards to ensure accuracy.

-

Material Compatibility: Ensure that the instrument’s materials are compatible with the fluid or gas being measured to prevent corrosion or contamination.

-

Temperature Consideration: Select instruments that compensate for temperature effects when measuring MPa Units in extreme conditions.

-

Pressure Range Selection: Use a gauge or sensor with a range that ideally spans 1.5 to 2 times the maximum expected pressure in MPa Units.

Common Measurement Errors and How to Avoid Them

-

Over-range Operation: Using a gauge with too low a maximum pressure rating can permanently damage it.

-

Incorrect Unit Conversion: Always confirm that the instrument displays or outputs pressure in MPa Units if that’s your standard.

-

Vibration and Pulsation Effects: These can cause needle flutter in analog gauges; use liquid-filled gauges or dampeners.

Maintenance and Calibration of MPa Instruments

-

Routine Checks: Visual inspection for cracks, leaks, or corrosion.

-

Calibration Schedule: At least once a year for most industrial applications using MPa Units.

-

Traceability: Ensure all calibrations trace back to national or international standards to maintain credibility and regulatory compliance.

Measuring pressure in MPa Units accurately is fundamental for safe and efficient operations. Choosing the right instrument, understanding its application limits, and maintaining it regularly ensures that the readings in MPa Units remain trustworthy. Whether you’re working in a lab, on a production floor, or in the field, having the right tools for measuring MPa Units is essential for success.

Up next, we’ll explore how MPa Units are applied in engineering industries like civil, mechanical, automotive, and aerospace.

MPa Units in Engineering Applications

In the realm of engineering, accurate measurement and understanding of pressure and stress are foundational. MPa Units (Megapascals) are essential in expressing these quantities across a wide variety of disciplines. From calculating material strength to ensuring system integrity, MPa Units play a critical role in daily engineering practice.

Why Engineers Use MPa Units

MPa Units provide a convenient and standardized way to express large amounts of pressure or stress. Unlike smaller units such as pascals, MPa Units simplify calculations and make data interpretation easier, especially in high-pressure scenarios. Engineers use MPa to evaluate the limits of materials, optimize systems, and ensure safety and regulatory compliance.

1. MPa Units in Civil Engineering

Civil engineers regularly use MPa Units to describe the compressive strength of materials, particularly concrete. The structural integrity of buildings, bridges, and dams depends heavily on accurate pressure and stress calculations.

-

Concrete Strength: Typically ranges from 20 MPa (residential construction) to 50+ MPa (high-rise buildings and infrastructure).

-

Soil Bearing Capacity: Expressed in MPa Units during geotechnical investigations to determine how much load the ground can support.

Example: A concrete mix with a strength of 30 MPa can withstand 30 million pascals of compressive force per square meter.

2. MPa Units in Mechanical Engineering

In mechanical systems, MPa Units are used extensively to determine internal stresses in components and systems under load.

-

Stress and Strain Analysis: Calculating tensile and compressive stresses during design and failure analysis.

-

Material Testing: Yield strength, ultimate tensile strength (UTS), and fatigue limits are typically reported in MPa.

-

Finite Element Analysis (FEA): Simulations often output results in MPa Units to help engineers visualize stress distribution.

Example: A steel shaft may be rated to withstand 250 MPa before deformation, ensuring reliability under operating conditions.

3. MPa Units in Automotive Engineering

Automotive engineers depend on MPa Units for numerous design, testing, and maintenance procedures.

-

Tire Pressure: Performance tires may operate around 0.2–0.3 MPa.

-

Engine Cylinder Pressure: Can reach up to 10 MPa or higher during combustion.

-

Brake System Hydraulics: Use MPa ratings to ensure proper force transmission and safety.

Example: A brake system operating at 3 MPa provides sufficient pressure to activate calipers effectively and stop the vehicle safely.

4. MPa Units in Aerospace Engineering

In aerospace, where materials are exposed to extreme stress, temperature, and pressure, MPa Units are vital for design and certification.

-

Fuselage and Wing Stress: Structural stress in aircraft skins and frames is often analyzed in MPa.

-

Jet Engine Pressure Ratios: Turbine components face pressures exceeding 4 MPa.

-

Fuel and Hydraulic Systems: Designed with strict MPa-based pressure limits to prevent failure in flight.

Example: The pressure containment strength of an aircraft’s fuselage might be tested to 0.7–0.9 MPa during cabin pressurization.

5. MPa Units in Materials Science and Testing

Materials are often rated and selected based on stress tolerances measured in MPa Units.

-

Hardness Testing: Some techniques correlate to stress ratings in MPa.

-

Failure Analysis: Investigates how and when materials exceed their MPa-rated limits.

-

Welding and Fabrication: Joint strength is expressed in MPa for quality control and certification.

6. Other Industrial Applications

MPa Units extend beyond traditional engineering sectors:

-

Oil & Gas: Wellhead pressure can exceed 70 MPa in deep wells.

-

Hydraulics and Pneumatics: MPa is standard for specifying operating ranges of equipment like pumps and actuators.

-

Manufacturing Equipment: Presses, extruders, and molds all rely on MPa ratings for design and operation.

Benefits of Using MPa Units in Engineering

-

Universality: Standard across SI systems and understood globally.

-

Convenience: Makes large pressures easy to express and interpret.

-

Consistency: Used across disciplines, improving cross-functional communication.

-

Precision: Enables engineers to fine-tune designs and ensure safety margins.

From the foundation of skyscrapers to the power of jet engines, MPa Units provide the precision, consistency, and reliability required to engineer safe, high-performance systems. Their widespread use across civil, mechanical, automotive, and aerospace disciplines reflects the versatility and necessity of this standard unit of measurement. As technology evolves, MPa Units will remain a cornerstone of engineering calculations and applications.

MPa Units in Material Testing

Material testing is an essential process in engineering and manufacturing, used to assess the strength, durability, and reliability of materials under various conditions. One of the most critical metrics in these tests is stress, which is commonly measured using MPa Units. In this context, MPa Units provide a standardized way to quantify how much force a material can withstand per unit area before deforming or failing.

Using MPa Units in material testing allows engineers and researchers to make informed decisions about material selection, component design, and safety margins. Accurate stress values in MPa are fundamental to ensuring that materials perform as expected in real-world applications.

1. Tensile Strength Testing in MPa Units

Tensile strength is the maximum stress a material can endure while being stretched or pulled before breaking. This is one of the most common and important tests performed in material science.

-

Ultimate Tensile Strength (UTS): Typically reported in MPa Units.

-

Yield Strength: The point at which the material begins to deform plastically, also measured in MPa.

-

Elongation at Break: While this is a percentage, it complements MPa-based stress data.

Example: A structural steel sample might have a UTS of 400 MPa and a yield strength of 250 MPa.

2. Compressive Strength Testing in MPa Units

This test measures a material’s ability to resist loads that would reduce its size. It’s especially relevant in construction materials like concrete, stone, and ceramics.

-

Concrete Compressive Strength: Usually expressed in MPa Units, with typical values ranging from 20 MPa to over 50 MPa.

-

Metal Compression Testing: Used in applications where materials experience heavy compressive loads.

Example: A concrete sample tested to failure may show a compressive strength of 30 MPa, suitable for residential construction.

3. Shear and Torsion Testing

-

Shear Stress: Evaluates a material’s response to forces that cause layers to slide against each other.

-

Torsional Strength: Measures a material’s resistance to twisting forces.

Both are expressed in MPa Units, helping engineers evaluate how materials behave under multidirectional stress.

Example: An aluminum alloy might withstand shear stress up to 200 MPa before shearing occurs.

4. Fatigue and Endurance Testing

Fatigue testing involves repeatedly applying stress to a material until it fails, often at levels much lower than the UTS.

-

Fatigue Limit: The stress level below which a material can theoretically endure an infinite number of cycles, expressed in MPa Units.

-

High-cycle and Low-cycle Fatigue Testing: Both rely on precise MPa measurements to determine performance under different conditions.

Example: A steel alloy with a fatigue limit of 150 MPa can be used in cyclic loading environments like engine components.

5. Hardness Testing Correlated with MPa Units

While hardness itself is not typically expressed in MPa, many hardness tests (like Vickers and Brinell) can be mathematically converted to approximate stress levels in MPa Units. This makes it easier to relate surface hardness to expected performance under load.

6. Fracture and Impact Testing

Fracture mechanics examine how materials behave when cracks are present.

-

Fracture Toughness: Indicates the stress (in MPa√m) a material can withstand in the presence of a crack.

-

Charpy and Izod Impact Tests: Measure energy absorption, with results often linked to stress levels in MPa for failure analysis.

7. Data Presentation in MPa Units

Test results are almost universally presented in graphs and tables using MPa Units, which offer clarity and comparability across materials and industries. This includes:

-

Stress-strain curves

-

Load vs. deformation graphs

-

Failure point identification

Benefits of Using MPa Units in Material Testing

-

Standardization: Facilitates global collaboration and comparison of materials.

-

Accuracy: Provides high-precision values for safety-critical applications.

-

Versatility: Suitable for metallic, ceramic, polymeric, and composite materials.

-

Clarity: Reduces complexity when dealing with high-force environments.

Whether evaluating tensile strength, compressive load capacity, fatigue resistance, or fracture behavior, MPa Units serve as the cornerstone for meaningful, accurate, and standardized material testing. Their use not only ensures precise measurement and safety but also enables innovation in material science by providing engineers with the confidence to push the limits of design.

MPa Units in Hydraulic and Pneumatic Systems

Hydraulic and pneumatic systems are integral to countless industrial, automotive, and construction applications. These systems operate by transmitting force through pressurized fluids or gases, making pressure measurement a central component of design and operation. Among the various pressure units available, MPa Units (Megapascals) are the preferred standard in many high-pressure systems due to their precision, simplicity, and international acceptance.

Importance of MPa Units in Fluid Power Systems

In both hydraulics (liquid-based systems) and pneumatics (gas-based systems), performance is directly linked to pressure. Using MPa Units helps engineers and technicians monitor, control, and design systems accurately. Whether powering industrial robots or controlling aircraft landing gear, consistent measurement in MPa Units ensures optimal functionality and safety.

MPa Ratings in Hydraulic Systems

Hydraulic systems typically operate at high pressures, making MPa Units ideal for measurement and regulation.

-

Typical Operating Ranges:

-

Light-duty systems: 2–5 MPa

-

Standard industrial systems: 10–25 MPa

-

Heavy-duty equipment: Up to 35 MPa or more

-

-

Applications:

-

Construction equipment (e.g., excavators, bulldozers)

-

Manufacturing presses

-

Hydraulic lifts and brakes

-

Example: A hydraulic press may operate at 20 MPa, meaning the fluid exerts a force of 20 million pascals per square meter, enough to form metal sheets or stamp components.

MPa Ratings in Pneumatic Systems

Pneumatic systems operate at lower pressures compared to hydraulics, but MPa Units are still commonly used to ensure standardized readings and controls.

-

Typical Operating Ranges:

-

0.2 to 1.0 MPa (equivalent to 2 to 10 bar)

-

-

Applications:

-

Factory automation (e.g., pneumatic actuators)

-

Air tools

-

Packaging and conveying systems

-

Example: A pneumatic actuator rated at 0.6 MPa delivers sufficient force for precise, repeatable motion in an assembly line.

Measuring Instruments in Fluid Systems Using MPa Units

To monitor and maintain pressure in hydraulic and pneumatic systems, various instruments are calibrated in MPa Units:

-

Pressure Gauges: Analog and digital versions directly display pressure in MPa.

-

Pressure Sensors and Transducers: Feed MPa-based data to control systems.

-

Relief Valves: Set and calibrated using MPa thresholds to prevent overpressure.

-

Regulators: Adjust downstream pressure and often include MPa Unit markings.

System Design Using MPa Units

When designing hydraulic and pneumatic circuits, engineers use MPa Units to:

-

Select pressure-rated hoses, seals, and fittings.

-

Determine the required power input and output.

-

Set safety margins and load capacities.

-

Optimize energy consumption.

Formula Example:

Force (N) = Pressure (MPa) × Area (mm²) × 1,000

This equation helps engineers calculate the force generated by a piston when pressure is expressed in MPa Units.

MPa-Based Safety Considerations

Pressure-related failures can lead to equipment damage or personal injury. By using MPa as the standard unit:

-

Safety valves and burst discs are correctly rated.

-

Maintenance intervals are better managed.

-

Training for operators is consistent and internationally standardized.

Regulatory and Industry Standards

Most fluid power systems are governed by international standards that specify the use of MPa Units, such as:

-

ISO 4413 for hydraulics

-

ISO 4414 for pneumatics

-

ASME and SAE standards for fittings and pressure components

These standards mandate using MPa Units in technical documentation, ensuring consistency and compliance.

Standards and Regulations Governing MPa Units

The use of MPa Units (Megapascals) in pressure measurement is not arbitrary—it is guided by a range of international standards and industry-specific regulations. These frameworks ensure consistency, safety, and precision across engineering disciplines, especially where high-pressure systems are involved. By adhering to recognized standards, manufacturers, engineers, and technicians can trust that their systems meet the requirements for performance and safety, regardless of geographic location.

Why Standards Matter for MPa Units

Standardizing the use of MPa Units enables:

-

Interoperability: Ensures components from different manufacturers work together.

-

Safety Assurance: Reduces risk of failure in high-pressure applications.

-

Regulatory Compliance: Helps companies meet legal and industry obligations.

-

Quality Control: Supports uniform testing and documentation practices.

Using MPa Units in accordance with standards simplifies communication in international projects, minimizes translation errors, and improves reliability in engineering designs.

Key International Standards That Use MPa Units

1. ISO Standards (International Organization for Standardization)

ISO sets global standards for measurement, manufacturing, and system performance. Many of these standards reference MPa Units directly:

-

ISO 76 – Rolling bearings — Static load ratings (stress in MPa)

-

ISO 898 – Mechanical properties of fasteners (yield and tensile strength in MPa)

-

ISO 4014 / ISO 4017 – Bolt specifications and tensile stress ratings in MPa

-

ISO 19973 – Pneumatic fluid power components — Use of MPa Units for pressure life testing

2. ASME Standards (American Society of Mechanical Engineers)

ASME publishes design codes for pressure vessels, piping, and mechanical systems, and often references MPa Units:

-

ASME Boiler and Pressure Vessel Code (BPVC): Includes tensile and yield strengths in MPa.

-

ASME B31.1 / B31.3: Process piping standards that calculate allowable stress in MPa.

-

ASME Y14.5: Dimensioning and tolerancing for mechanical drawings, which may specify stress or pressure limits in MPa Units.

3. ASTM Standards (American Society for Testing and Materials)

ASTM standards govern material testing and reporting formats, including the expression of results in MPa Units:

-

ASTM E8/E8M: Tensile testing of metallic materials (results in MPa).

-

ASTM A370: Mechanical testing of steel products, including stress in MPa Units.

-

ASTM D638: Testing tensile properties of plastics using MPa Units for clarity.

4. EN Standards (European Norms)

The European Committee for Standardization (CEN) ensures regional compliance with MPa-based measurements:

-

EN 10025: Steel structural products with mechanical properties in MPa.

-

EN 1092-1: Flanges and their pressure-temperature ratings (in MPa).

Industry-Specific Regulations Requiring MPa Units

-

Oil and Gas (API standards): MPa Units are used in pressure ratings for valves, fittings, and pipes (e.g., API 6A, API 1104).

-

Automotive (SAE standards): Component testing and material strengths are listed in MPa Units.

-

Construction Codes: National codes (e.g., Eurocode, ACI) use MPa Units for concrete compressive strength.

-

Aerospace and Aviation: International aerospace standards express critical stress and pressure specifications in MPa Units.

Certification and Calibration Standards

-

ISO 17025: Specifies general requirements for the competence of testing and calibration laboratories—often referencing MPa Units for pressure instruments.

-

NIST (National Institute of Standards and Technology): Provides traceability and reference values for MPa-based pressure measurement in the U.S.

Compliance Documentation Using MPa Units

When reporting test results, designing systems, or producing user manuals, engineers and manufacturers are often required to:

-

Report material properties in MPa Units

-

Display pressure ratings in MPa on nameplates and labels

-

Show calculations in MPa-based stress units for audit trails and legal review

Regulatory Agencies That Reference MPa Units

-

OSHA (Occupational Safety and Health Administration) – U.S.

-

EU Machinery Directive

-

Japan Industrial Standards (JIS)

-

CSA Group (Canada)

These agencies align with international norms that encourage or require the use of MPa Units to ensure uniform safety and performance metrics.

Standards and regulations play a vital role in shaping how MPa Units are used globally. By aligning with ISO, ASME, ASTM, and other leading bodies, professionals ensure their systems are compliant, reliable, and safe. For any pressure-related application—from bolts and valves to pressure vessels and pipelines—MPa Units serve as the trusted benchmark that bridges national boundaries and unifies technical language across industries.

Calculating and Interpreting MPa Units

Understanding how to calculate and interpret MPa Units is essential for professionals working in engineering, construction, manufacturing, and materials testing. As a measure of pressure and stress, MPa Units (Megapascals) quantify how much force is applied over a specific area. The ability to accurately calculate and interpret these values ensures safe design, effective analysis, and reliable system performance.

Basic Formula for MPa Units

The Megapascal (MPa) is defined as one million pascals:

1 MPa = 1,000,000 Pa = 1,000,000 N/m²

To calculate pressure or stress in MPa Units, use the following general formula:

MPa = Force (N) / Area (mm²) × 1,000

This formula converts Newtons per square millimeter into MPa by applying the proper conversion factor (1 MPa = 1 N/mm²).

Example 1: Calculating Tensile Stress in MPa Units

Problem:

A force of 50,000 N is applied to a steel rod with a cross-sectional area of 200 mm². What is the tensile stress?

Solution:

MPa = 50,000 N / 200 mm² = 250 MPa

This means the material is experiencing a tensile stress of 250 MPa.

Example 2: Calculating Hydraulic Pressure in MPa Units

Problem:

A hydraulic piston has an area of 1500 mm², and a force of 30,000 N is exerted. What is the pressure?

Solution:

MPa = 30,000 N / 1500 mm² = 20 MPa

This pressure is well within the range of many industrial hydraulic systems.

Interpreting MPa Units in Practice

Understanding MPa Units goes beyond calculation—it involves context, comparison, and decision-making.

1. Material Strength

-

Yield strength of structural steel: ~250 MPa

-

Ultimate tensile strength (UTS) of carbon steel: ~400–550 MPa

-

Concrete compressive strength: ~20–50 MPa

Interpreting these numbers helps in selecting suitable materials for different loads and environments.

2. Design Safety Factors

Engineers apply safety factors by comparing actual operating stress (in MPa Units) to the material’s yield strength:

Safety Factor = Yield Strength / Actual Stress

A higher safety factor ensures that even under unexpected loads, the material will not fail.

Using MPa Units in Engineering Software

Modern engineering software often uses MPa Units as the default for pressure and stress outputs. Programs like:

-

ANSYS, SolidWorks, and Abaqus for stress analysis

-

AutoCAD and Revit for construction modeling

-

MATLAB for custom simulations

By interpreting MPa-based results, users can validate system safety, predict failure points, and optimize designs.

Reading Graphs and Test Data in MPa Units

Stress-strain graphs are one of the most common visuals in material testing:

-

The x-axis represents strain (% deformation)

-

The y-axis represents stress in MPa Units

Key points on the graph:

-

Yield point: Where permanent deformation begins

-

Ultimate strength: Maximum stress before necking

-

Fracture point: Final failure

Interpreting these values in MPa helps assess the suitability of a material for specific applications.

Common Mistakes in MPa Calculations

-

Incorrect area units: Always use mm² or convert accordingly.

-

Forgetting conversion factors: 1 MPa = 1 N/mm² or 1,000,000 N/m².

-

Misapplying formulas: Ensure force and area align in units before calculation.

-

Ignoring dynamic factors: MPa ratings are often static—real-world dynamic loads may exceed calculated limits.

Online Tools and Calculators for MPa Units

-

UnitConverterFree.com

-

EngineeringToolBox.com

-

Custom calculators embedded in engineering websites or apps

Being able to calculate and interpret MPa Units accurately is essential for ensuring the reliability, safety, and effectiveness of engineered systems. Whether analyzing stress in a steel beam or determining the pressure in a hydraulic line, mastering MPa Units equips professionals with a universal language of pressure and strength. With proper tools, formulas, and awareness of context, MPa-based measurements become a powerful resource in any technical field.

Common Mistakes and Misunderstandings about MPa Units

Despite being a standard unit in engineering and science, MPa Units (Megapascals) are sometimes misunderstood or misused, leading to serious errors in calculations, reporting, or system design. Whether due to improper conversions, confusion with other units, or a lack of contextual understanding, these mistakes can compromise safety, performance, and compliance.

Understanding the most common mistakes related to MPa Units can help professionals avoid costly and dangerous outcomes.

1. Confusing MPa with Other Pressure Units

One of the most frequent errors is confusing MPa Units with similar-sounding or visually comparable pressure units such as:

-

psi (pounds per square inch)

-

bar

-

kg/cm²

-

Pa (pascal)

Mistake Example: A technician mistakenly assumes that 1 MPa = 1 bar instead of the correct conversion:

1 MPa = 10 bar

This error could result in a tenfold underestimation of system pressure, potentially leading to catastrophic failure.

2. Incorrect Unit Conversions

Even when users know that conversion is required, misapplying conversion factors is common.

-

Forgetting to multiply by 1,000,000 when converting from MPa to Pascals (Pa)

-

Using 1 MPa = 100 psi instead of the accurate 145.038 psi

-

Rounding too early or inaccurately in critical pressure calculations

Tip: Always double-check conversion factors and use reliable calculators when working with MPa Units.

3. Using Inconsistent Units in Calculations

Another common issue is mixing units during calculations—especially when force is given in newtons and area in cm² or m² without proper conversion.

Incorrect Example:

MPa = 50,000 N / 50 cm² → wrong unless area is converted to mm²

(Correct: Convert 50 cm² = 5000 mm²)

4. Assuming All Industries Use MPa Units

While MPa Units are standard in many countries and industries, some regions (e.g., the United States) still use psi more frequently. Assuming that everyone uses MPa can lead to communication errors and mismatched system components.

Best Practice: Always confirm the unit standard in technical documents and specifications.

5. Neglecting Dynamic Conditions in MPa Ratings

MPa ratings on materials or equipment often reflect static conditions. In real-world applications, systems face dynamic loads, temperature variations, and vibration—all of which may exceed the nominal MPa rating.

Misunderstanding: Assuming a 25 MPa-rated hose will always withstand 25 MPa in all conditions.

Reality: The hose may fail under repeated pressure spikes or extreme heat.

6. Ignoring Temperature and Environmental Effects

Material behavior under pressure can change significantly with temperature. MPa values calculated or measured at room temperature may not apply in extreme environments (e.g., cryogenics or high-heat systems).

Solution: Use temperature-compensated testing or refer to pressure ratings specific to the operating environment.

7. Incorrectly Reading Instrument Scales

Many pressure gauges show multiple scales (MPa, psi, bar). It’s easy to misread the wrong scale if not careful.

Example: A gauge may show 3 on the psi scale and 0.2 on the MPa scale. Assuming it’s 3 MPa is incorrect and could lead to critical errors.

8. Relying on Uncalibrated Instruments

Measurements in MPa Units are only as reliable as the instruments used. Using uncalibrated, damaged, or low-quality equipment can produce false readings.

Recommendation: Ensure all instruments measuring in MPa are regularly calibrated and certified.

9. Misinterpreting Material Strength Data

Materials are often rated by tensile strength, yield strength, or fatigue limit—all in MPa Units. A common misunderstanding is assuming one MPa rating covers all failure types.

Clarification:

-

Yield strength tells you when a material begins to deform.

-

Ultimate tensile strength tells you when it breaks.

-

Fatigue strength tells you how it performs under cyclic loads.

These values differ and are all measured in MPa Units for precision.

10. Improper Labeling and Documentation

Incorrect or missing units on blueprints, datasheets, or labels can create confusion or misinterpretation. A missing “MPa” notation might lead someone to assume psi or bar is being used.

Tip: Always label values clearly and consistently as MPa Units in documentation.

Conclusion

MPa Units—short for Megapascals—are far more than just a numerical expression of pressure or stress. They are a foundational unit of measurement used throughout engineering, manufacturing, material science, and construction. From calculating tensile strength in a laboratory to monitoring hydraulic pressure in a heavy-duty excavator, MPa Units play a vital role in ensuring systems are safe, efficient, and engineered to perform under pressure.

This article explored the definition and significance of MPa Units, their practical applications across various fields, and the common conversions that professionals must understand. We examined how MPa Units are measured using instruments like gauges and sensors, how they are applied in industries such as civil, mechanical, automotive, and aerospace engineering, and how they guide critical material testing processes. Additionally, we reviewed relevant standards and regulations, discussed calculation methods, and highlighted common mistakes to avoid when working with MPa Units.

As technology continues to advance and global collaboration in engineering becomes even more interconnected, MPa Units will remain a universally accepted, reliable standard. Their precision and versatility help bridge industries, simplify communication, and uphold the rigorous quality and safety expectations demanded by modern engineering.

By mastering the use and interpretation of MPa Units, professionals gain a crucial tool for making informed decisions, preventing failures, and pushing the boundaries of innovation. Whether you’re designing skyscrapers, testing aircraft components, or simply converting pressure units, MPa Units offer the clarity, consistency, and confidence that today’s technical challenges require.